Packaging Inspection Systems

Inspecting packaging during production is essential for maintaining product quality, safety, and compliance. Our packaging inspection systems check for seal integrity, leaks, micro-holes, and other packaging defects, while also verifying labels, codes, and weights. By catching issues on the line, these systems help prevent defective packs from reaching the market, reduce waste and recalls, and ensure consistent quality — protecting both your products and your brand reputation.

Table of Contents

ALL-IN-ONE Food Inspection

An innovative solution, unique on the market, including all the needed inspections in one single system. Simply identify your inspection requirements, Antares Vision Group - ALL-IN-ONE will meet them all thanks to our wide range of technologies, integrating multiple checks in one compact machine.

Benefits:

- Reduced footprint

- One control panel

- Quick product changeover

- One electrical/pneumatic connection

- Reduced Total Cost of Ownership (TCO) compared to three single machines

- Compliance with all legal requirements (possibility of MID approval) and market (HACCP, BRC, IFS, etc. certifications)

Label and Code Inspection

Knowing you have the right information on your packs is critical to consumer safety and your brand reputation. These systems by Antares Vision Group check the quality of labels (alignment, positioning, items or brand, languages, etc.), codes (expired data, lot number, barcode, Data Matrix, QR code) and the correlation between single products and secondary packaging.

Benefits:

-

100% inspection of every product on the line.

-

Strong brand protection with fewer returns.

-

Flexible handling of product shapes and label types.

-

Advanced imaging, AI, and 3D modelling for accuracy.

-

Real-time defect detection and rejection to cut waste.

-

Reads all major codes: 1D, 2D, QR, and alphanumeric.

-

Customisable to specific retail requirements.

Leak and Seal Inspection

An innovative application of IR spectroscopy to detect inline holes and microholes in packages by checking for CO2 leakage (for MAP products), alcohol or a specific flavour. In-line sealing area inspection to detect the presence of products and physical contaminants. Available for transparent or coloured film and packaging through hyperspectral or artificial vision technologies.

Benefits:

-

100% in-line, non-destructive inspection of all packages

-

Detection of leaks, micro-holes, seal faults, and contaminants

-

Maintains line speed and product integrity (no compromise to modified atmospheres)

-

Automatic rejection of defective items in real time

-

Reduced product returns, waste, and reliance on manual checks

-

Customisable solutions to retail or process specification

X-Ray Food Inspection

Antares Vision Group inspection technology uses X-rays to identify foreign bodies of different densities. It generates a grayscale image of the product and the software, through a multi-algorithm analysis, highlights contaminants and rejects non-compliant items.

Benefits:

-

Detects high-density contaminants (glass, metal, stones, bones, plastics).

-

Versatile inspection for multiple product types and packaging formats.

-

Seamless integration into production lines.

-

User-friendly interface with advanced software.

-

Compliant with international standards without extra radiological monitoring.

-

Remote assistance capabilities for support and maintenance.

Metal Detection Systems

By detecting the presence of metal contamination, Antares Vision Group metal detectors for food provide effective protection against ferrous and non-ferrous metals (aluminium, stainless steel, etc.) and guarantee customer safety.

Benefits:

-

Ensures the absence of metal contaminants, safeguarding product and consumer safety.

-

Ergonomic, hygienic design compliant with cleaning standards for quick maintenance.

-

Simultaneous multi-frequency technology for high reliability and efficiency.

-

Versatile models for horizontal, vertical, and bulk products.

-

Customisable to retail specifications, meeting specific operational needs.

Checkweigher Systems

Antares Vision Group checkweighers are high-precision measuring instruments designed to check the weight of individual products. On board reporting and networking allows you to see your line efficiency in real time and guarantees the right weight for the consumer.

Benefits:

-

High-precision verification of individual product weights, ensuring regulatory compliance.

-

Real-time reporting and networking for line efficiency and data management.

-

MID-approved and designed for easy sanitisation and versatility.

-

Seamless integration with external systems and Industry 4.0 readiness.

-

Remote assistance capabilities to reduce maintenance costs.

-

User-friendly 12” touchscreen for full system control and product recipes.

-

Customisable to retail specifications and operational needs.

Combi Inspection Systems

Antares Vision Group's Combi systems integrate multiple inspection functions, like X-ray, metal detection, and checkweighing, into a single compact unit. These versatile solutions enhance product safety and quality, handling various product types while optimising efficiency and ensuring compliance with industry standards.

Benefits:

-

Combines multiple inspections (metal, X-ray, checkweighing) in one unit.

-

Compact and ultra-compact designs for space‑restricted environments.

-

User-friendly 12” touchscreen for easy operation.

-

Integrated systems can operate independently for production flexibility.

-

Customisable for specific products and operational needs.

VacuCheck

CLK's VacuCheck is a high-speed, non-contact inspection system designed to detect the smallest leaks in vacuum-sealed pouch bags. Utilising advanced camera technology and AI-powered image processing, it identifies nearly 100% of defective packages, ensuring product integrity and minimising the risk of costly recalls. The system integrates seamlessly into existing production lines, operating hygienically above the conveyor belt without direct product contact. With easy retrofitting capabilities and robust design, VacuCheck enhances efficiency and maintains stringent quality standards in food packaging processes.

Benefits:

- Detection rate: almost 100%

- Objective assessment with constant evaluation criteria compared to human inspection

- Coupling to an automatic ejection system possible

- Easy integration into an existing line

- Constructed according to hygienic design guidelines

- Adaptation of the system to local conditions possible

- Automatic email notification in case of malfunctions

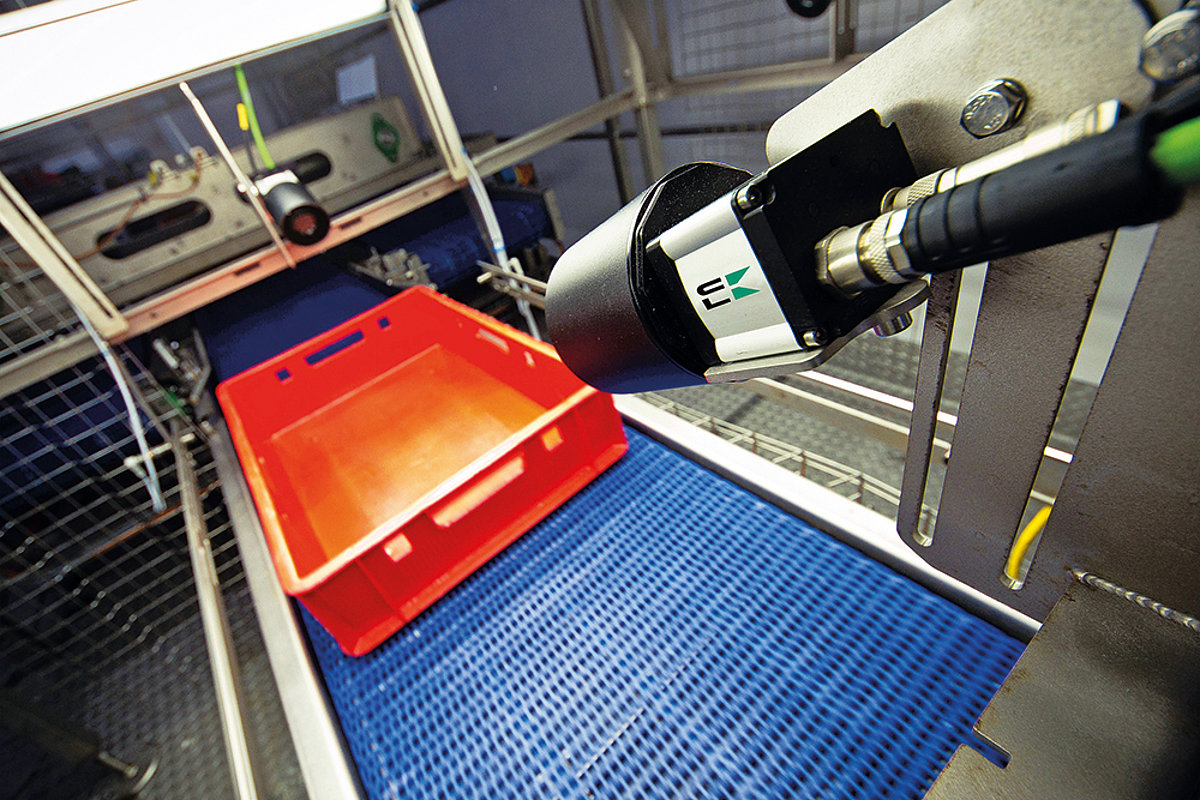

BoxCheck

CLK's BoxCheck is an advanced optical inspection system designed to ensure the cleanliness and integrity of E1 and E2 multi-purpose containers. Using six high-resolution cameras, it detects internal contamination, label residues, and structural defects such as cracks or holes in the container base. Operating at speeds of up to 2,500 containers per hour, BoxCheck integrates seamlessly into production lines, providing real-time detection and sorting. Its robust, IP67-rated housing guarantees reliable performance in demanding food processing environments. With features like remote maintenance, self-diagnostics, and comprehensive data logging, BoxCheck helps improve operational efficiency and maintain product quality.

Benefits:

- Reduced product loss

- Minimized downtime

- Flexible adjustment of inspection parameters

- Robust hardware with IP67 protection

- Inspection of up to 2500 pieces/hour

- Database connection for comprehensive evaluation

- Data collection for optimizing the washing machine settings

DokuStation

CLK's DokuStation streamlines the documentation of commissioned pallets, capturing comprehensive images with a single button press. Integrated with optical identification code reading, it automatically sorts and stores data, reducing manual effort and minimising errors. Designed for high-speed environments, it operates with minimal user interaction and requires no additional lighting, ensuring efficient and reliable documentation. This system enhances traceability and simplifies evidence retrieval, supporting quality assurance and complaint resolution processes.

Benefits:

-

Seamless documentation of your goods with minimal effort

-

Simplified evidence for complaints

-

Nearly any placement at the optimal logistics position is possible

-

Easy operation

-

Status display ensures correct documentation

-

Special and high-quality industrial cameras guarantee long life and long-term availability

-

No separate lighting required with sufficient hall lighting

Microwave Food Inspection

Foreign bodies that X-rays and metal detectors fail to detect are detected by inspection with microwave technology. Plastic, glass, wood, bones, rubber, insects, and all metals, regardless of their size or composition, are from now on detectable. This is a new solution developed by the Antares Vision Group – register your interest to find out more.

Empty Container Inspection

Antares Vision Group's Empty Container Inspection systems are designed to detect defects in cans and bottles before filling. These intelligent solutions use advanced vision technology and AI to ensure containers are free from contaminants, deformations, or residues—improving product safety, reducing waste, and minimising downtime.

Benefits:

-

Detects scratches, fragments, deformations, and flange/shape defects in empty cans and bottles.

-

Uses AI-driven vision for accurate, efficient inspection.

-

Suitable for various can sizes and bottle shapes.

-

High-speed operation for seamless production integration.

-

Provides records and image storage for traceability.

-

Expandable with additional inspection modules.

Fill Level and Cap Inspection

Antares Vision Group’s Fill Level and Cap Inspection Systems combines advanced technologies to ensure accurate fill levels and secure, compliant closures. These compact, high-speed solutions detect issues like underfills, foam, misapplied caps, and tamper band defects—boosting efficiency, reducing waste, and maintaining consistent product quality across liquid packaging lines.

Benefits:

-

100% in-line inspection for every product.

-

Detects defects, contaminants, and mislabelling to ensure product quality.

-

Real-time rejection of faulty products to reduce waste.

-

Versatile and customisable for different products, packaging formats, and retail requirements.

-

Advanced technology (AI, vision systems, X-ray, multi-frequency) for accurate, reliable inspection.

-

User-friendly interfaces with data recording for traceability and compliance.

-

Supports seamless integration with production lines and Industry 4.0 systems.

Gas Concentration Measurement

Antares Vision Group’s advanced Gas Concentration Measurement solutions are non-destructive systems that use laser spectroscopy to monitor O₂ and CO₂ levels, to help ensure packaging integrity, detect microbial spoilage, and optimise shelf-life. Ideal for MAP and quarantine applications, they offer fast, accurate insight into product quality and safety across a wide range of food packaging formats.

Benefits:

-

Non-destructive monitoring of O₂ and CO₂ in sealed packages.

-

Ensures correct gas mixtures for MAP products and optimal shelf-life.

-

Detects microbial contamination via CO₂ variations.

-

Suitable for all sealed packaging formats without consumables.

-

Reliable, repeatable measurements with automatic temperature compensation.

-

Ideal for dairy, meat, and other food sectors.

Serialisation

Antares Vision Group's cutting-edge serialization and vision systems for the food industry are designed to ensure full traceability, compliance, and quality control. From in-line code printing and inspection to 360° code reading and multi-code linking, these solutions boost transparency, prevent counterfeiting, and preserve packaging aesthetics with invisible UV marking options.

Benefits:

-

Ensures full product traceability across the supply chain.

-

Verifies code integrity and uniqueness in real time.

-

Supports various packaging formats and orientations.

-

Integrates seamlessly into existing production lines.

-

Enhances supply chain transparency and protects against counterfeiting.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Food safety – Inspection and detection

Automated food quality and safety inspection solutions The Challenge The presence of micro-holes in food packaging is a particularly critical problem in...

Read the full Case Study