Poultry

The poultry sector, like any other, faces huge demand for convenience packaging. More than ever before, consumers want products which are easy to grab, prepare and consume.

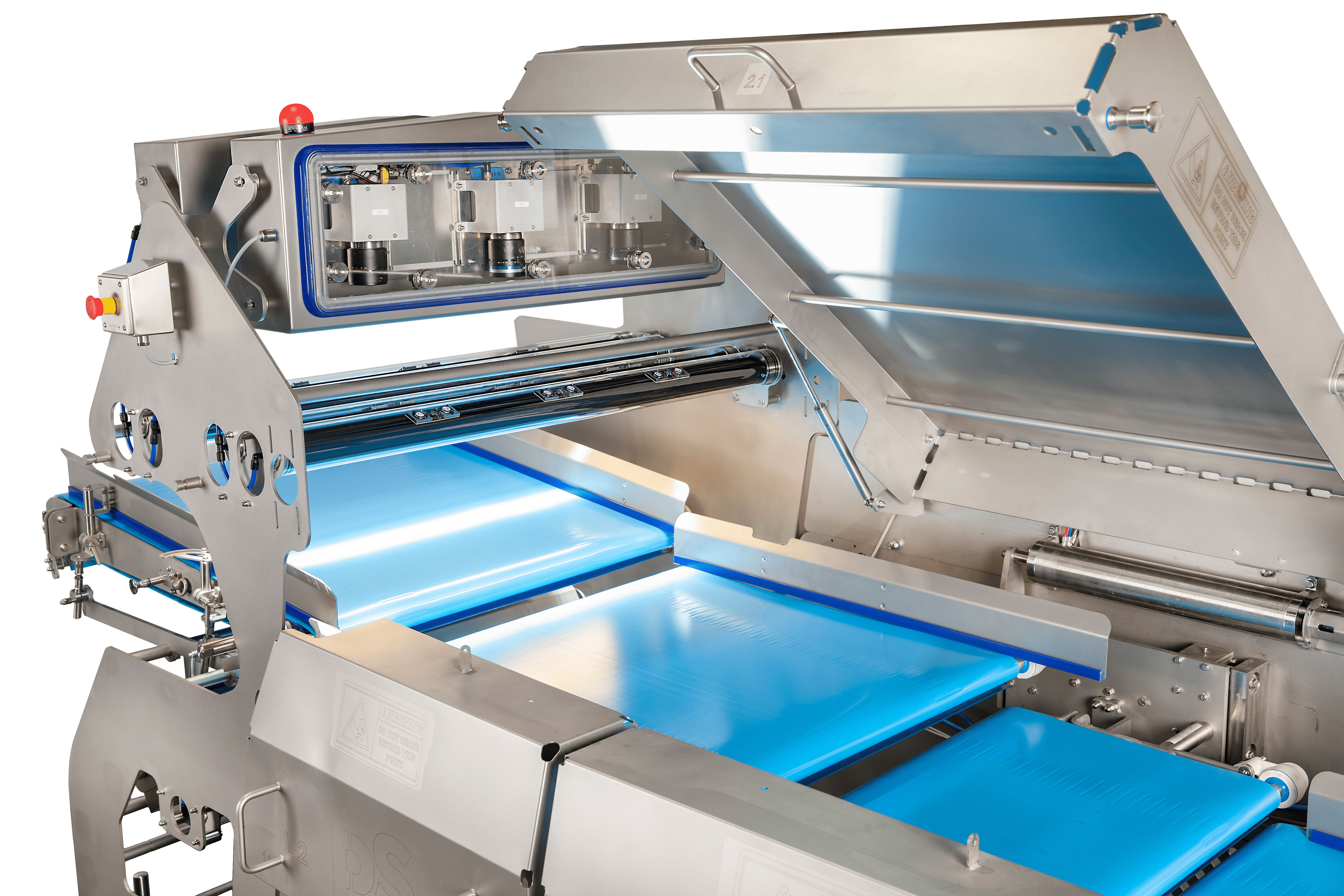

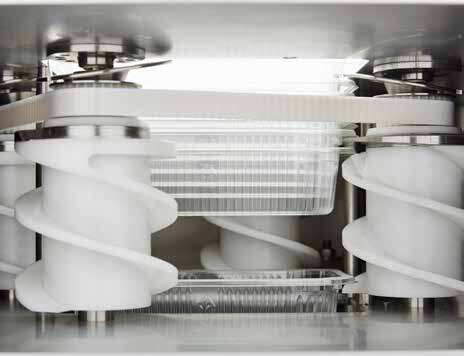

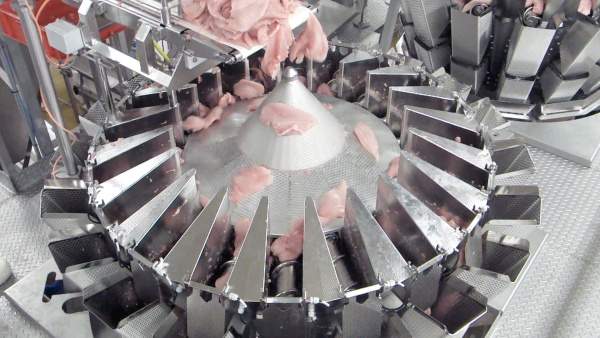

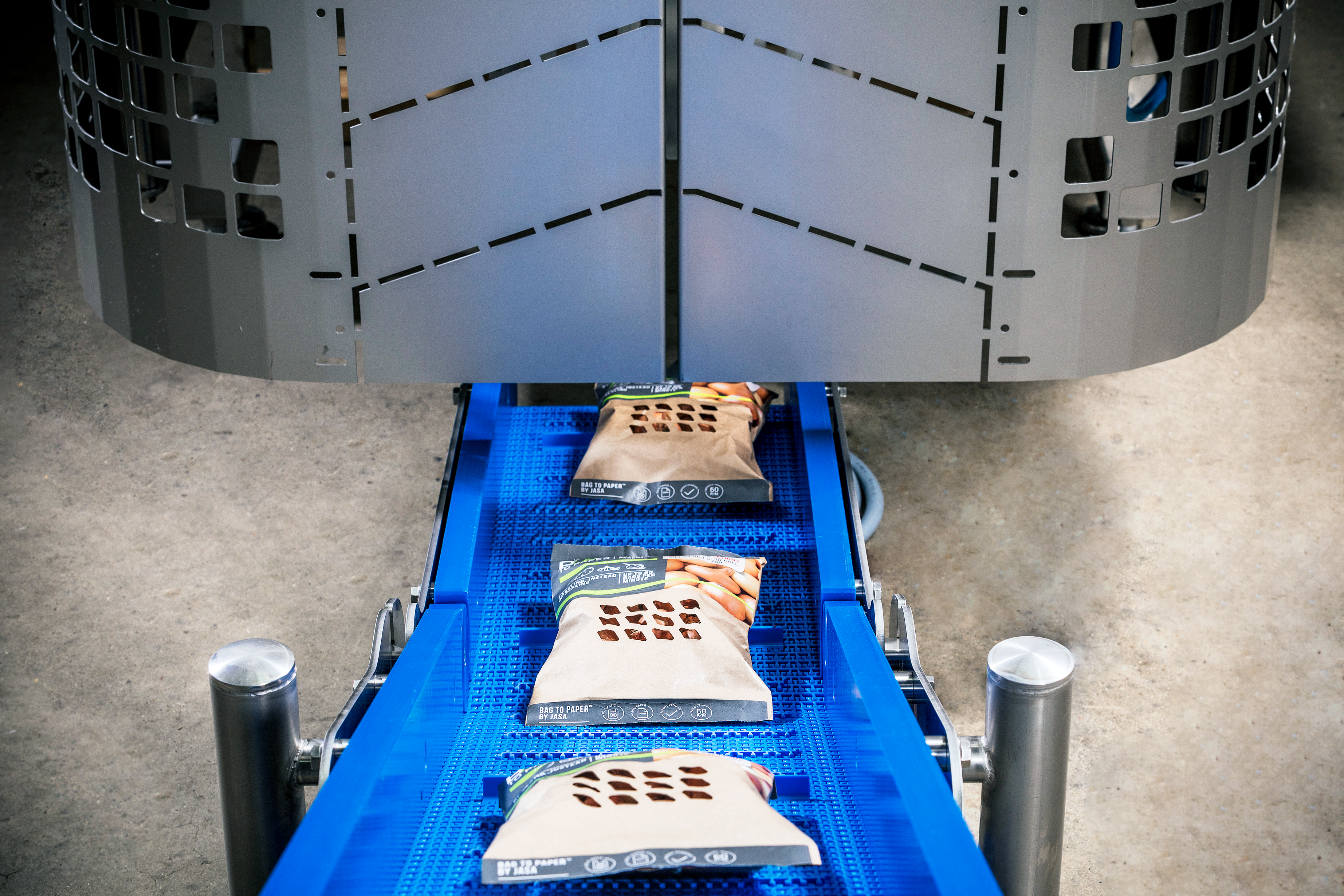

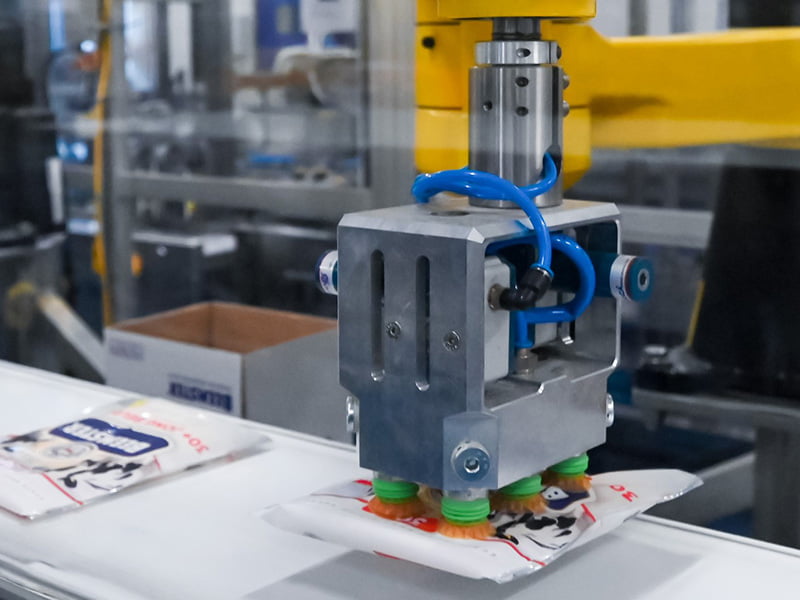

Be ready for anything with our flexible range of full-line solutions. Sealpac UK & Partners are glad to offer automated solutions to streamline the production process, from sorting, to weighing and packing, and packaging to quality control, we’ve got you covered.

A range of packaging solutions for ready-to-eat and ready-to-cook products

Increased freshness and improved shelf life

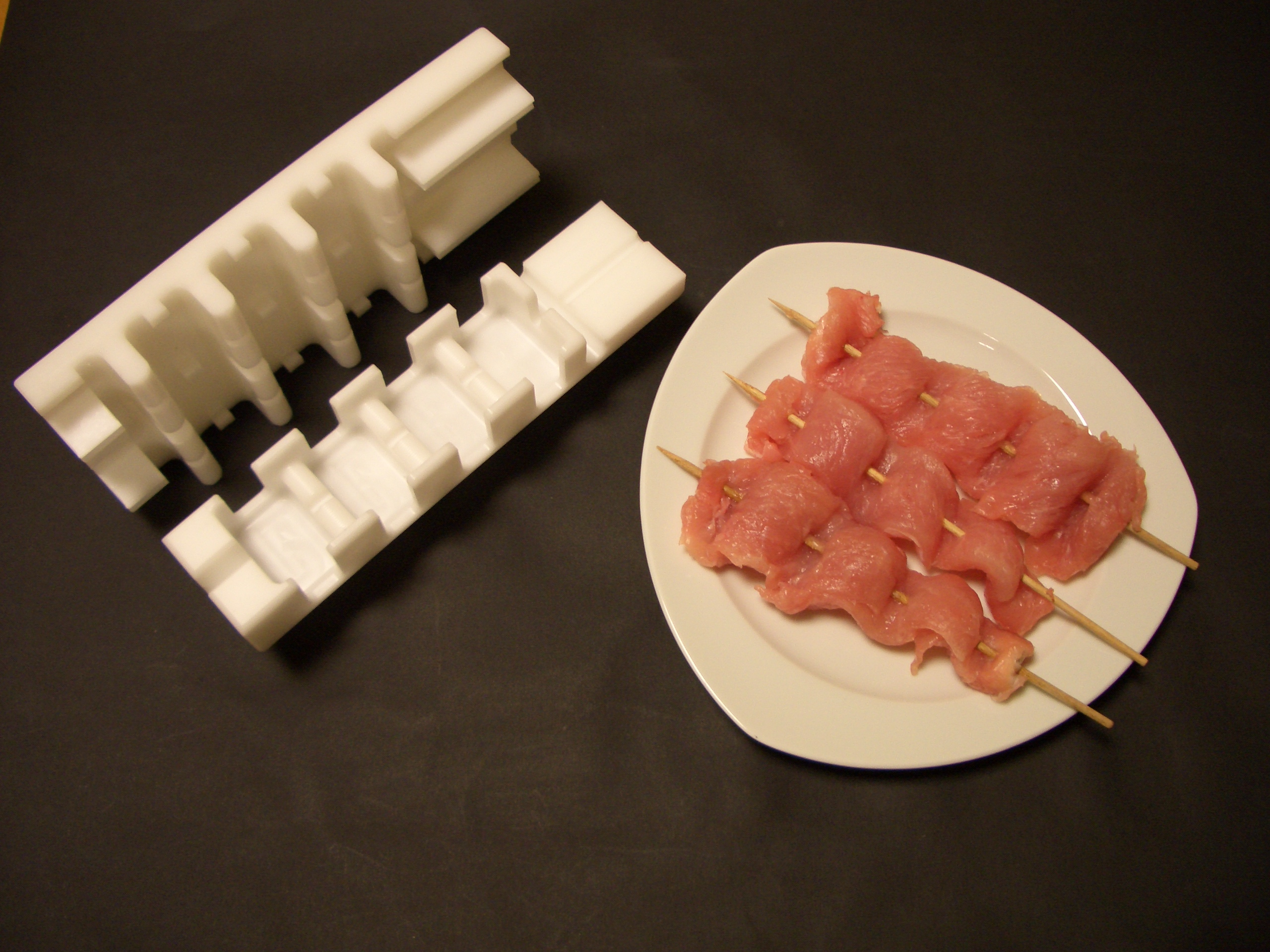

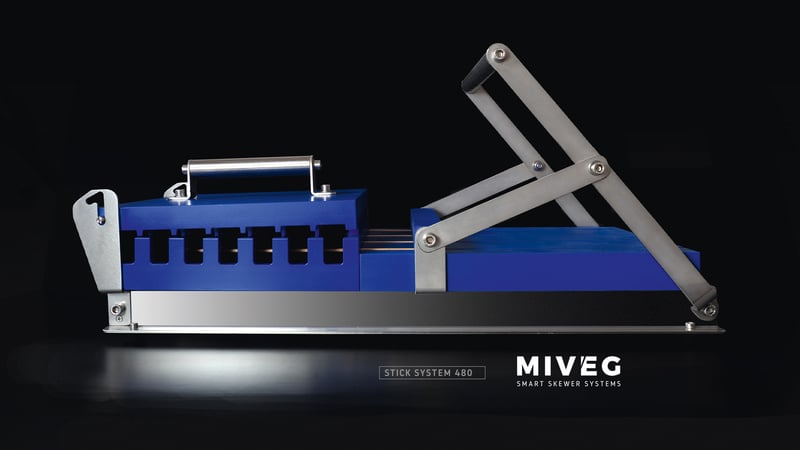

Smart skewering systems

Effortless and careful handling of marinated meats

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.