Processing

Optimise your food processing and production lines with smart solutions, saving energy and time

We are proud to offer solutions in processing and handling with our partners Cabinplant, DGS and Nippon Career Industries for solutions with energy saving automated systems from cooking, blanching, slaughtering, slicing and cold store handling. Systems are easily integrated in to your factory giving you many benefits to optimise and maximise profit.

Features and Benefits

Automate and re-deploy your workforce

The investment in automating your process lets you re-deploy your key staff in other areas of the factory where they are needed most. Automated solutions improve output, reduce giveaway and drive efficiency to help lower the cost of production.

Reduce waste and energy consumption

Reduce costs through efficiency

Increase return on investment

Blanchers and Coolers

Given the delicate nature of most produce and seafood, it's imperative to employ gentle processing equipment to safeguard their essential nutritional attributes and delightful flavor. Through our partnership with Cabinplant, we offer premium blanchers and coolers meticulously crafted to ensure the preservation of your product's crucial nutritional properties, as well as its consistency and appearance, both of which are paramount. With precise water flow control, product temperature management, and retention time in the blanching process, we ensure the retention of taste, color, nutrients, and vitamins within the product.

Find out more

Slicing

Precise automation with a hand made look...

Introducing the impressive slicing systems from Nippon Career Industry. These unique slicing systems have several benefits including:

- No crust freezing required

- Slices fresh meats from 1mm to 20mm

- 70 slices per minute

- Single or twin slicing

- Auto sharpening

- Waste automatically vacuumed away

Slaughter lines

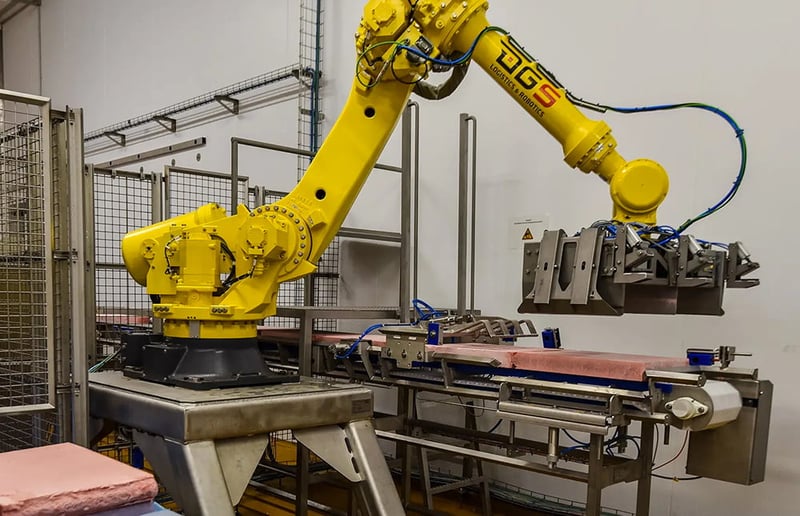

Our partners at DGS provide customised solutions for the food processing industry. Systems have been developed to optimise customer-specific processes. As a result, they are recognised by clients for the high level of quality and efficiency that the systems offer them. Would you also like to optimise the processes within your organisation? We’re happy to sit down with you and bounce ideas around in order to find the most suitable solution for your operation. For years, the team at DGS have been delivering innovative custom systems that ensure higher returns, highly efficient and hygienic processes and an ergonomic working environment for your employees.

Thor Ice Chilling Processs

We partner with Thor Ice to provide solutions for efficiently chilling fresh products like fish, poultry, and meat throughout the entire food value chain: from processing through distribution to consumption. The technology, utilising slurry ice, offers enhanced control and distribution compared to traditional methods like cold air, flake ice, chilled seawater, or regular ice cubes. The modular Thor Ice platform seamlessly integrates with existing chilling systems, utilising specialised IceGuns® to spray slurry ice precisely onto products, optimising cooling efficiency and reduces labor, waste, and energy costs.

Find out more

Thawing and defrosting

Cold store solutions

Tailor-made solutions for cold stores help you optimise the refrigerating process. On the primary side there are various methods such as manually operated conveyors, automatic buffer conveyors and walking beams, to the automation for rapid cooling. These various systems can be integrated into your current operation. You can also speed up and optimise the chilling and freezing process after packing with our process optimisations for pallet freezing and carton freezing of fresh product. With our racks and software, we have developed systems that manage your process automatically and flawlessly.

Hygienic Transport Systems

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Automating Skewer Production with the MIVEG 7200

The Challenge A major UK food manufacturer faced growing pressure to scale up its BBQ skewer production. Their existing line relied heavily on manual...

Read the full Case Study

-

Case Study

Installing A High-Speed Salad Layering Line With Sealpac UK and Partners

The Challenge A customer had recently taken on the production of layered salad and pasta products from another supplier. These were complex and tricky...

Read the full Case Study

-

Case Study

Automating Noodle Weighing and Distribution

The Challenge The customer faced several challenges with their existing noodle weighing and distribution system. The process required multiple operators...

Read the full Case Study