About Us

Sealpac UK & Partners are the UK leaders in full line, end-to-end solutions. With our unrivalled expertise, we have a long and proven track record of designing, installing and maintaining lines across a broad range of sectors. Put us to the test – you won't regret your decision.

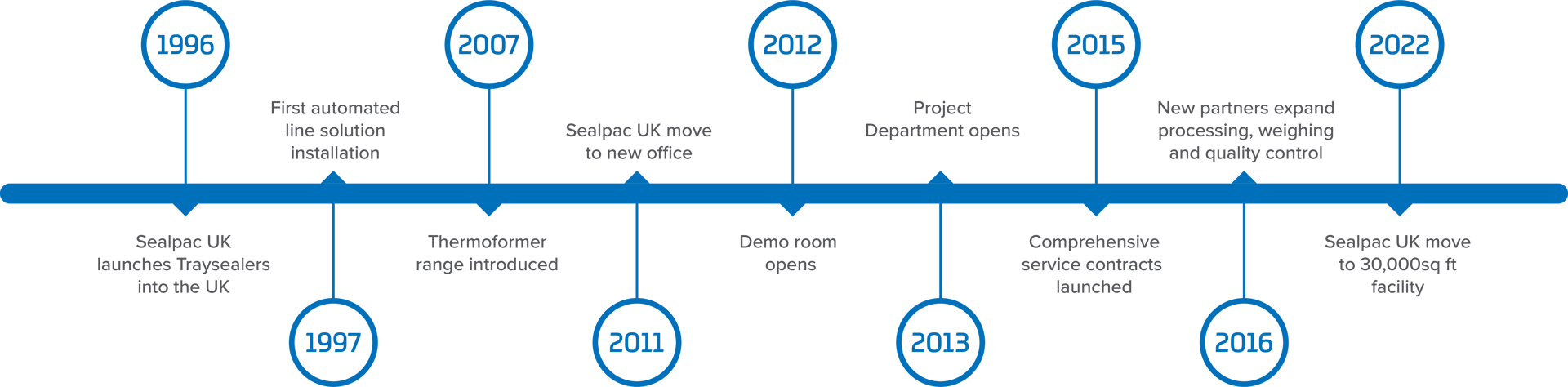

A history of expertise and excellence

Sealpac UK first started to work closely with Sealpac GmbH in 1996, building a strong partnership that saw the development and introduction of Traysealing machines into the UK packing industry. Soon after that we delivered our first line solution project, working closely with a customer to bring the concept to life including tray handling, weighing, depositing and sealing in a single, seamless line.

Since then, by forming strategic partnerships with other suppliers and manufacturers, we are now Sealpac UK & Partners. These partnerships have enabled us to expand our offering, utilising the very best technologies available to ensure that we can deliver the most complex, flexible and efficient line solutions available. Our ever-improving product range covers processing, weighing, depositing, packaging machine options, quality control and case packing – we can truly cover every aspect of the line.

From the beginning we have remained focused on 3 core strengths which are at the heart of our business:

- Highly Experienced and knowledgeable people

- The very best range of quality machinery

- Class-leading after sales, support and training

Today our project team manages anything from a simple standalone machine up to a full line. We take complete ownership of the project and we work hand in hand with our customers to deliver tailored, sophisticated fully-automated line solutions.

This is all backed up by our class leading after-sales team who can offer service & maintenance packages, along with expert training and advice on how to maximise efficiency. And this is all backed up by an unrivalled spare parts service that will keep downtime to an absolute minimum; we have even despatched spares by taxi for a same-day emergency service.

With such a long pedigree and many delighted customers, we are rightly proud of our many successes. So whatever your line requirements, put us to the test – we WILL deliver for you.