Skewering Machines

From handmade-style skewers to fully automated solutions with adjustable speeds of up to 120 kebabs per minute, our machines offer flexible, labour-saving solutions while utilizing FSC Certified skewer materials.

Miveg, our trusted industry partner, boasts over 45 years of expertise in skewer systems. The high-speed skewer systems deliver a remarkable output of up to 5 million skewers per season, ensuring scalability for seasonal production peaks. With Miveg systems, maintaining consistent output during peak seasons is a breeze, thanks to their low maintenance and, in some cases, maintenance-free designs.

Scalable Output Guarantee

Variety of Systems

Maximum Product Variety

Flexibility to craft an extensive range of grill skewers like meats, poultry, cheese, fish, veggies, fruits, chocolates, candies, and other convenience products.

Skewering Guarantee

Types of Skewering Machines

Automated Skewer Systems

Skewer System 7200

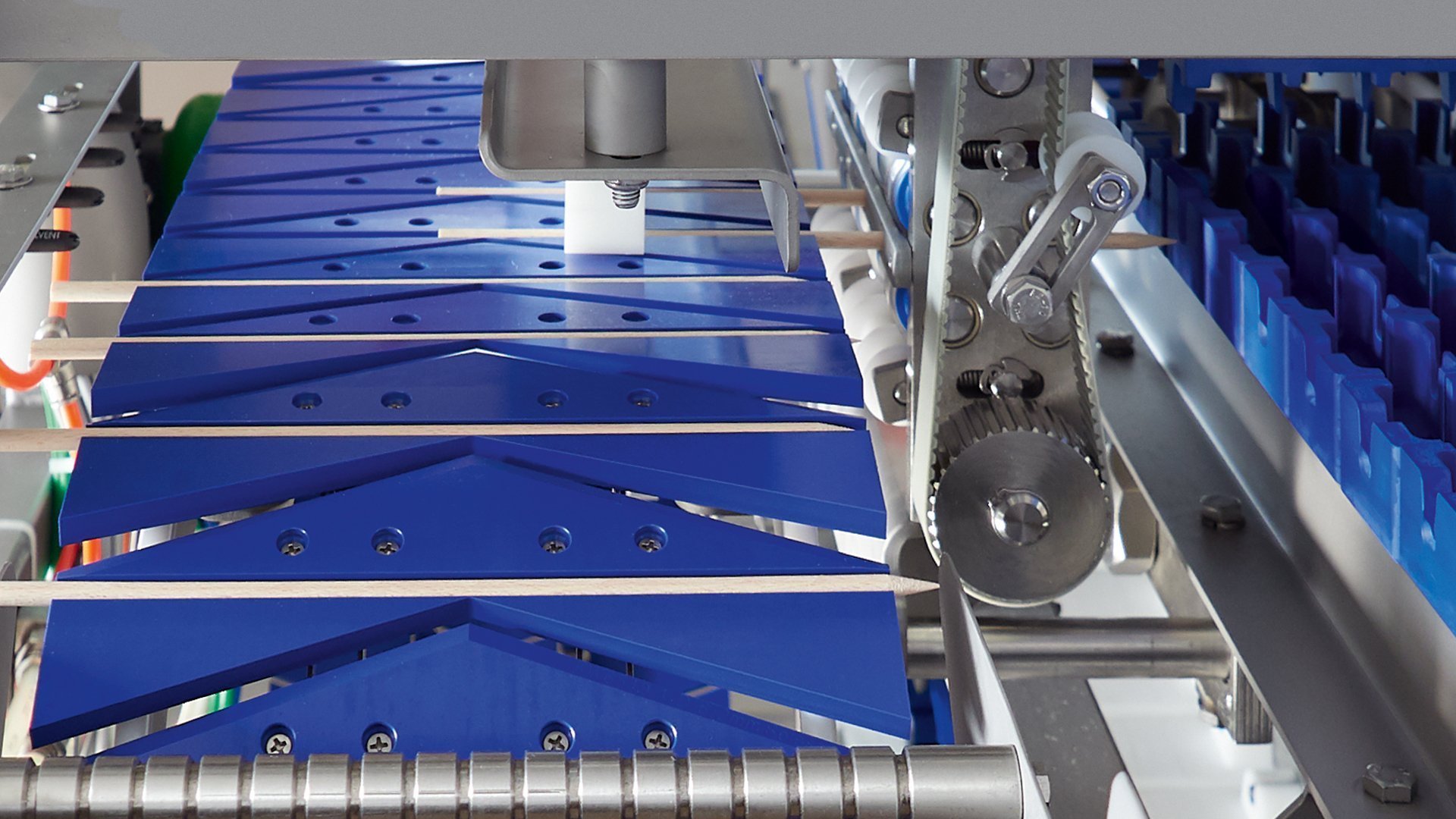

![]() Skewer System 7200 is designed to provide maximum reliability, flexibility, and scalability, ensuring you always have ample skewer capacity. It is a computer controlled system, serving as the successor to the highly successful Skewer System 4080.

Skewer System 7200 is designed to provide maximum reliability, flexibility, and scalability, ensuring you always have ample skewer capacity. It is a computer controlled system, serving as the successor to the highly successful Skewer System 4080.

Why choose the Skewer System 7200?

- Computer-controlled system accommodates a diverse range of products, like meat, cheese, fish, shrimp, sausages, etc.

- Individual cassettes available for customer specific products.

- Guarantees optimal efficiency, capable of producing an impressive range from 12 to 120 finished skewers per minute.

- Quick product changes and easy cleaning.

- Modular extensions available like automated loading and lean in place module.

- Guaranteed output of at least 95%

Skewer System 4080

Whether it's meat, poultry, minced meat, cheese, fish, or vegetables, the Skewer System 4080 helps you produce up to 4080 handmade-looking skewers per hour, requiring only 2-8 employees. The system's flexibility shows in its modular design, allowing seamless upgrades to a production line with features like automated loading, unloading, or the Clean in Place Module.

Whether it's meat, poultry, minced meat, cheese, fish, or vegetables, the Skewer System 4080 helps you produce up to 4080 handmade-looking skewers per hour, requiring only 2-8 employees. The system's flexibility shows in its modular design, allowing seamless upgrades to a production line with features like automated loading, unloading, or the Clean in Place Module.

Why choose the Skewer System 4080?

- Adjustable production rate from 8 - 68 skewers per minute

- Accommodates round and flat skewers.

- Suitable for meat, cheese, vegetables, fruit, fish, and sausages.

- Tailor-made product moulds to meet customer specifications.

- Quick product changes and easy cleaning.

- Guaranteed output of at least 95%.

Semi Automated Skewer Systems

Skewer System 1440

The revolutionary Skewer System 1440 allows you to craft up to 1440 ready-made skewers per hour, whether they're adorned with meat, poultry, minced meat, cheese, fish, or vegetables. The System 1440, designed for efficiency, operates seamlessly with 2-5 employees, ensuring a swift production process that maintains the look of handcrafted skewers - a testament to the system's quality.

The revolutionary Skewer System 1440 allows you to craft up to 1440 ready-made skewers per hour, whether they're adorned with meat, poultry, minced meat, cheese, fish, or vegetables. The System 1440, designed for efficiency, operates seamlessly with 2-5 employees, ensuring a swift production process that maintains the look of handcrafted skewers - a testament to the system's quality.

Why choose the Skewer System 1440?

- Produce skewers up to 250 mm in length with ease.

- Accommodates round skewers ranging from 3.2 to 3.8 mm in diameter.

- Capable of handling individual product moulds, including prototyping.

- Customized moulds designed to meet specific customer requirements.

- Each mould is easily replaceable and switchable for efficient production.

- For meat, cheese, vegetables, fish, sausages, etc.

- Less floor space required.

Wrap System 600

The Wrap System 600 is designed for the professional creation of bacon grill sticks and similar skewers. This innovative system ensures a secure grip of the meat on the skewer throughout key processes like seasoning, weighing, packaging, and barbecuing. With a remarkable capability of turning products around the skewer at rates reaching 600 sticks per hour, the rotation speed is customizable for optimal control.

The Wrap System 600 is designed for the professional creation of bacon grill sticks and similar skewers. This innovative system ensures a secure grip of the meat on the skewer throughout key processes like seasoning, weighing, packaging, and barbecuing. With a remarkable capability of turning products around the skewer at rates reaching 600 sticks per hour, the rotation speed is customizable for optimal control.

Why choose the Wrap System 600?

- Accommodates round, flat, and gun skewers (150-335 mm) with a diameter ranging from 3-8 mm.

- Available as a single unit for standalone operations or seamlessly integrated into a production line.

- Individual units can go upto 600 skewers per hour.

- Combine multiple units for a staggering production capacity of up to 4000 bacon grill sticks per hour.

Corndog Systems

A timeless American favorite with enormous potential. Now, you can bring this iconic treat to Europe! Corndogs, featuring savory sausages on a stick encased in crispy corn dough, have captured hearts and appetites across the globe.

Why choose the Corndog Systems?

- Up to 16,000 corndogs per hour

- Fast revenue in a thriving market.

- Systems available for small, manual productions to automated mass production.

- Perfect for street food, snacks, and all kinds of events.

- A wide variety of flavors and product combinations.

Manual Skewer Systems

Stick System 480

The Stick System 480 is tailored for marinated or natural meats, bacon, vegetables, or sausages.

- Effortlessly produce up to 480 grill skewers per hour.

- Round skewers, ranging from 3.2mm to 3.8mm in diameter and lengths spanning 80mm to 250mm.

- The system is versatile, allowing for the creation of gun skewers and flat skewers ranging from 120mm to 235mm in length.

- Tailored for counters, catering events, and parties.

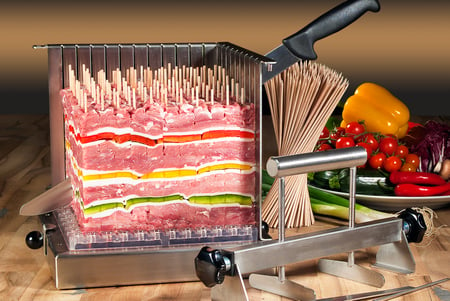

Stick Systems 108, 72 and 81M

The Stick Systems 108, 72 and 81M are efficient solutions for producing perfectly weighted skewers in just 20 minutes.

- Allows you to produce 108, 72 or 81 rectangular skewers, according to the unit, ranging from 40 to 120g each.

- Equipped with a specialised knife for precise skewer sizing and wooden skewers

- User-friendly and accessible for any staff member.

- Cube size accommodates 15mm to 25mm, while the wooden skewers are a diameter of 3.2mm and lengths ranging from 100mm to 235mm.

- Maximum filling capacity of 12.9kg for meat and vegetables

- Streamlines production and enhances overall efficiency.

- Tailored for counters, catering events, and parties.

Beech Wood Skewers

Miveg's premium Beech wood skewers are renowned for their exceptional quality, durability, and safety. They are crafted to withstand breakage during the skewering process, ensuring they last longer, these skewers are virtually fire-resistant, making them an ideal choice for a wide range of culinary applications.

- High-quality, durable skewers built to last.

- Length options from 80 to 800 mm to suit your needs.

- Diameters available from 3.0 to 10.00 mm for diverse applications.

- Customize your order of 10,000 or more with your logo on the skewers.

- BRC certified ensureing the highest food safety standards are met.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.