Sealpac Thermoformer Range

As consumer demands rise, the expectations for both food and non-food packaging in the industrial sector also escalate. Quality and freshness now hold equal significance alongside attractive visual presentation and first-class opening aids. Whether you're a mid-sized producer offering a diverse product line or a large-scale industrial entity, SEALPAC offers tailored packaging solutions. Our range includes efficient thermoformers of various sizes, designed for diverse applications, ensuring your products are packaged precisely to your specifications.

Types of Pack Styles Available

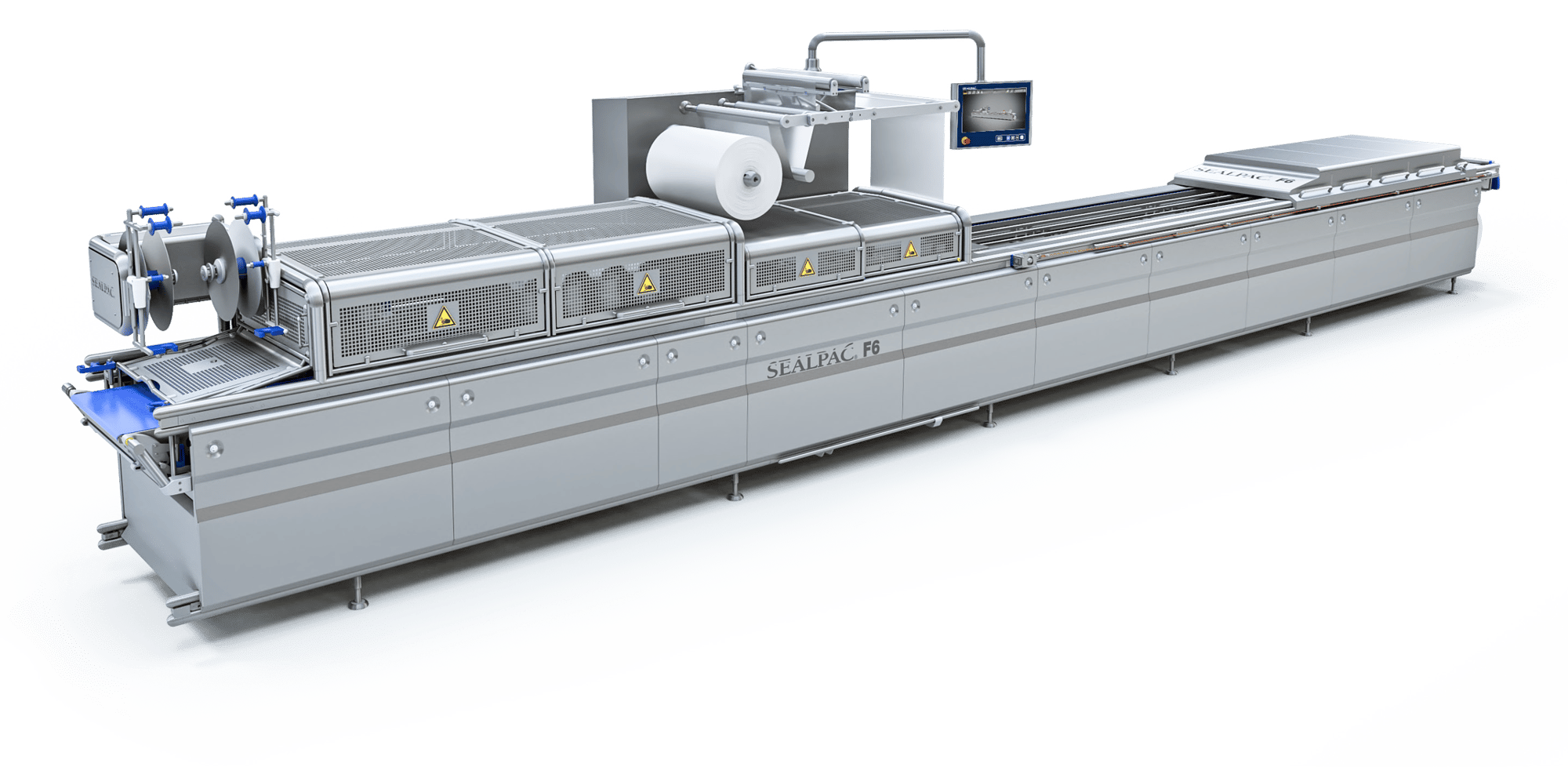

Sealpac F-Series Thermoformer Range

Our F-series thermoformers offer ultimate flexibility with quick-change tooling systems for minimal downtime and maximum safety. Smart algorithms optimise performance and energy use, while advanced forming technology delivers perfectly shaped packs—even with thinner films. A true Industry 4.0 solution designed for speed, precision, and adaptability.

- Exceptionally durable build quality: guarantees a long lifespan

- Fully servo driven

- Lowest maintenance costs

- Handles all flexible and rigid film applications

- Faster cycle times and thinner films due to unique forming system

- Tooling quick exchange systems: swift tool changes with minimum downtime

- Easy operation with intuitive touch-screen monitor and iModeControl and traceability due to RFID tags

- Industry-standard control software: in-line connectivity and easy network integration

- Smart: automated film alignment and chain tension correction

Ultimate Flexibility, Seamless Changeovers

Smart Efficiency, Long-Term Value

Precision Forming, Future-Ready Design

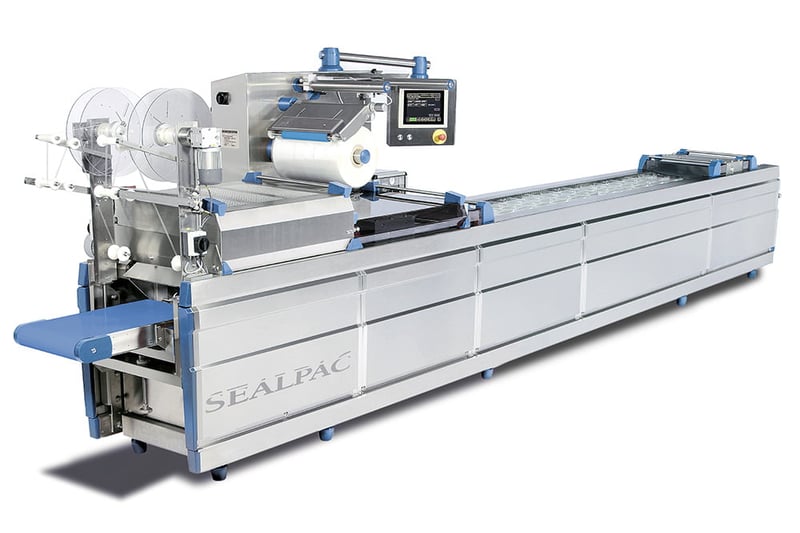

Sealpac PRO-Thermoformer Range

Explore the latest PRO-series thermoformers, ideal for diverse product ranges and production outputs. SEALPAC thermoforming machines share a commitment to high performance, precision, and efficiency, all within a compact footprint and cost-effective ownership. Tailor them to your specific requirements, starting with the versatile PRO thermoforming machine designed for vacuum packaging and sealing applications using flexible and rigid films.

- Compact footprint, spacious loading area

- Quick tooling exchange for minimal downtime during changeovers

- Rapid Air Forming enables faster cycles with thinner films

- Modular build for flexible customization

- Hygienic design with hinged side panels and open construction

- Intuitive operation via accessible touch-screen monitor

- Superior durability, top quality in its category

- Four-point lifting systems for optimal forming and sealing

- Reduced maintenance costs with smart valves and servo-driven chain

Maximum Performance, Minimum Space

Lowest Cost of Ownership

First Class Thermoforming Technology

Sealpac RE-Thermoformer Range

Whether you're a mid-sized producer with diverse products or a high-output industrial company, we've got your packaging covered. Our range includes efficient thermoformers for all needs, boasting advanced technology that enhances precision and efficiency in manufacturing. Regardless of the model you select, the RE-series thermoformers excel with future-oriented technology, robust construction, and cutting-edge materials.

- Versatile operation for common flexible and rigid film applications, including shrink and skin packaging.

- Quick exchange systems facilitate swift changeovers, minimizing downtime.

- Hygienic design ensures cleanliness and compliance with industry standards.

- Sturdy construction with easy access for maintenance purposes.

- Four-point lifting systems operate independently, optimizing forming and sealing processes.

- One-piece self-supporting frame (up to 6 meters) ensures structural integrity.

- Rapid Air Forming technology allows for faster cycle times and the use of thinner films.

- Intuitive touch-screen monitor for user-friendly operation.

- Low maintenance costs contribute to cost-effective operation.

From 8 to 15 cycles per minute

Highest Possible Level of Flexibility

Thermoformer Applications for Tomorrow's Markets.

RE15 - The Entry Level Professional

RE30 - The High-End Solution

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

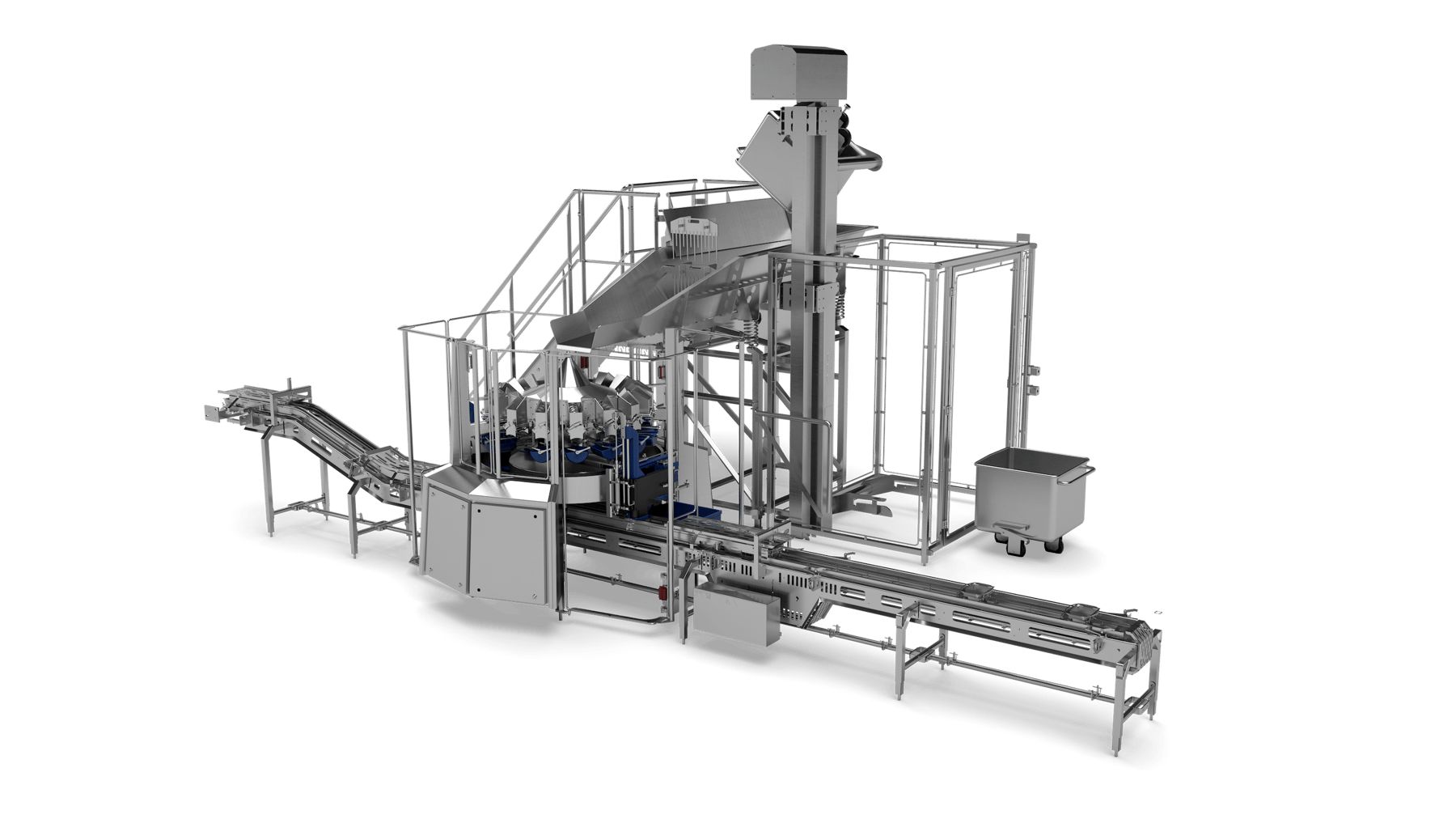

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.