SEALPAC Traysealer Range

SEALPAC stands as a prominent worldwide innovator in the realm of automated food packaging solutions. Within every machine, you'll witness the skill, commitment, and enthusiasm of seasoned engineers. The traysealers, distinguished by superior performance and precision, are marked by unparalleled reliability and efficiency. This is achieved through their robust construction, predominantly crafted from single-piece components produced in-house.

Table of Contents

Types of Pack Styles Available

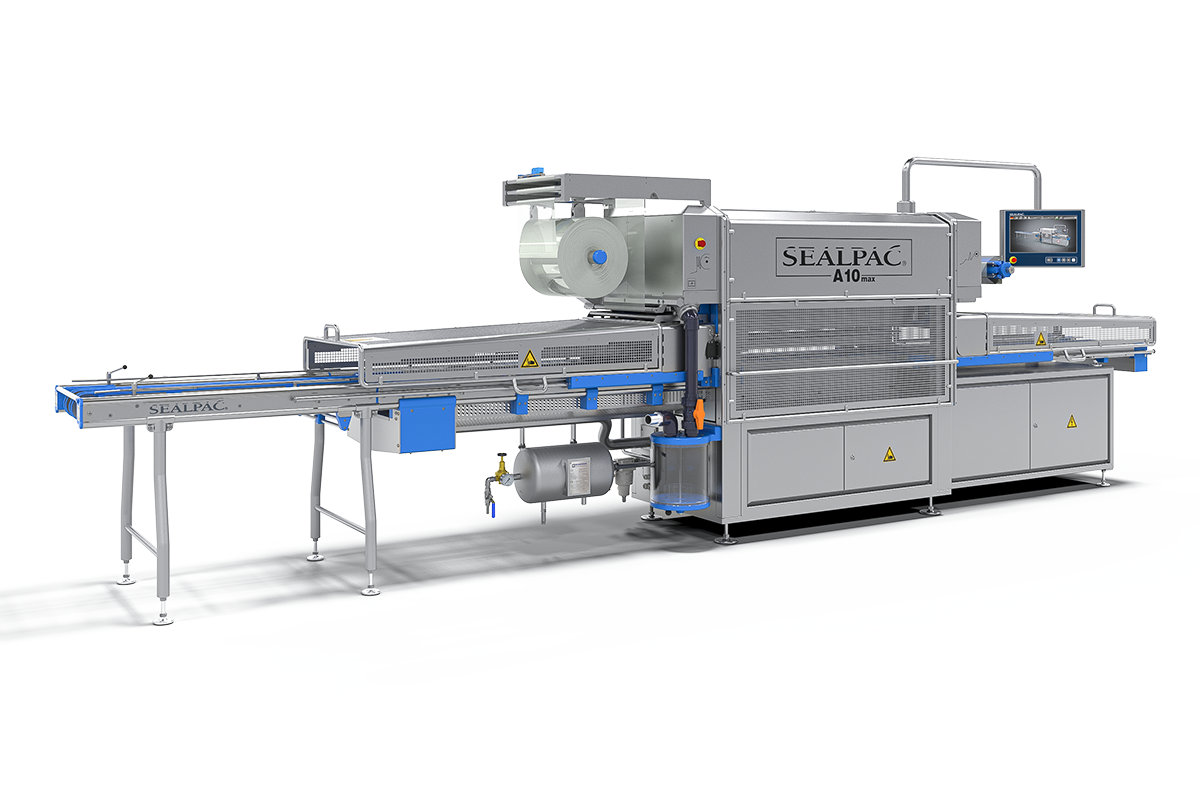

SEALPAC Traysealer Amax Range

Amax Traysealers are built with a strong focus on reliability and flexibility. The result is the most versatile and advanced machine incorporating AI technology.

- Any tray or film material - Mono/Mono, Card, Foil, APET, CPET, Fibre board, Plastic lined trays, and more

- Seal Only

- Modified atmosphere with vacuum

- Gas flush without vacuum

- Skin on plastic with protrusion

- Skin on card with protrusion

- Skin on foil with protrusion

- Reclose applications

- Inside cut

- Outside cut

- Separate compartment sealing

- Flat Card – MAP and Skin versions

- Clamshell trays with MAP

From 10 to 320 packs per minute.

From A4max - A10max, single and double lane.

Machines that think for themselves.

Download the Amax Traysealer Range brochure

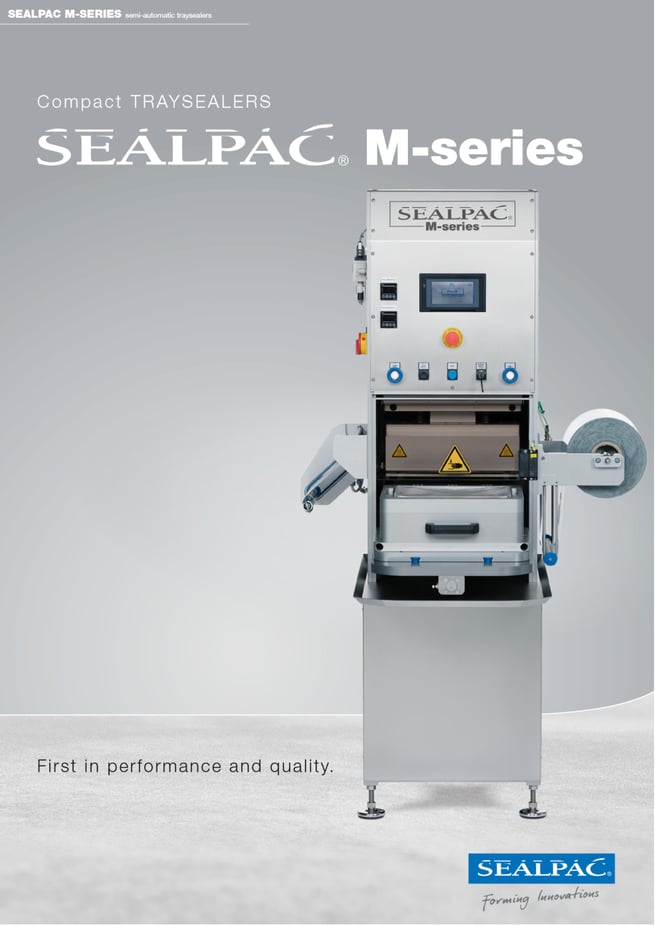

SEALPAC Traysealer M-Series Range

With a compact design, the SEALPAC M-series delivers unbeatable value. Built to the same high standards as the Amax-series, applications tested on our semi-automatic tray easily transition to the fully automated Amax-series.

- Any tray or film material - Mono/Mono, Card, Foil, APET, CPET, Fibre board, Plastic lined trays, and more

- Seal Only

- Modified atmosphere with vacuum

- Gas flush without vacuum

- Skin on plastic with protrusion

- Skin on card with protrusion

- Skin on foil with protrusion

- Reclose applications

- Inside cut

- Outside cut

- Separate compartment sealing

- Flat Card – MAP and Skin versions

- Clamshell trays with MAP

- Small footprint

- Hygienic Design

- Quick tooling exchange system for optimal flexibility

- Comes with all the proven Sealpac technologies.

- Easy to switch to the fully automated Amax-series.

Download the M-series Traysealer Range brochure

From 5 to 15 packs per minute

Packed with the latest technology.

Machines that think for themselves.

The MX Traysealer

The M-Flex Traysealer

How can you benefit from our experience?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.