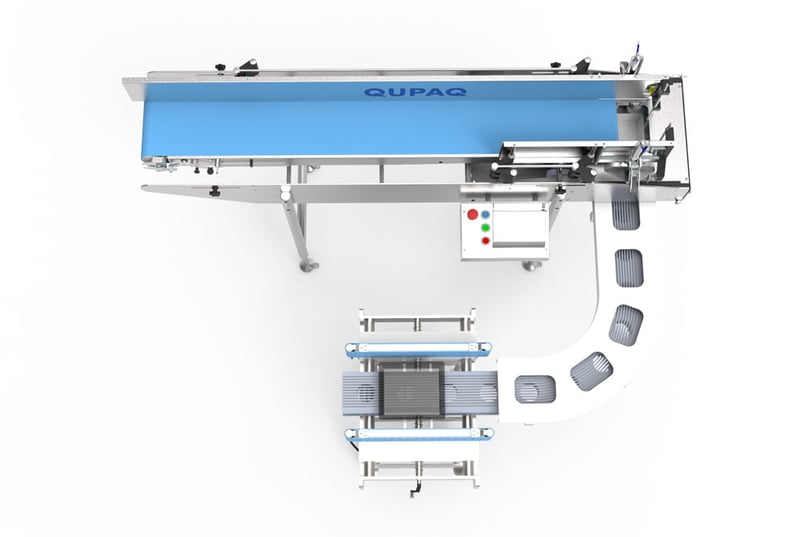

Browse through QUPAQ’s Tray Handling offering — a suite of high‑precision solutions built to re‑orient and distribute trays seamlessly through your line. Whether you need a tray turner to rotate trays gently (at speeds up to 120 trays/min) or a diverger to split flow across multiple conveyors, QUPAQ’s modular, servo‑driven systems integrate easily into both new and existing production setups.

Denesting & Tray Handling

Tray solutions for precise, flexible, and high-speed production lines

Higher speeds with less people

Maintain your flexibility

Intelligence built in

Suitable for all food packaging materials

Pick and place denesters

SEALPAC’s range of pick and place denesters offer the highest accuracy for placing trays on to a Traysealer conveyor. Available as single and double lane systems they pick multiple trays at a time and are synchronised with the production line for optimal performance. The units require no technical connections other than electrical power. Equipped with servo drive, they achieve an unparalleled denesting result. Each denester is easily integrated in new and existing food production lines.

Find out more

Scroll denesters

Our denester range from our partners QUPAQ are loaded with features to fit any type of food production line. The systems start from single outlet standalone units up to twin outlet with buffer conveyor to keep your food production line running with minimum operator interaction. Speeds up to 400 trays per minute can be achieved. The units are hygienically designed to IP67 for industrial cleaning and are easily maintained thanks to the simple design.

Find out more

Tray Handlers

Tray Loaders

Explore QUPAQ’s Tray Loader range — engineered for speed, precision, and ultimate flexibility. Whether you're loading delicate mince at up to 135 trays / min with the Fast Loader, switching between multiple products in a single tray with the Flex Loader (up to 260 portions / min), or using the Step Loader for recipe‑controlled, step‑by‑step multi‑product loading — each solution integrates seamlessly into your line. Hygienic, modular and scalable, QUPAQ’s tray loaders make automatic tray filling safe, efficient, and reliable.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Automating Skewer Production with the MIVEG 7200

The Challenge A major UK food manufacturer faced growing pressure to scale up its BBQ skewer production. Their existing line relied heavily on manual...

Read the full Case Study

-

Case Study

Installing A High-Speed Salad Layering Line With Sealpac UK and Partners

The Challenge A customer had recently taken on the production of layered salad and pasta products from another supplier. These were complex and tricky...

Read the full Case Study

-

Case Study

Automating Noodle Weighing and Distribution

The Challenge The customer faced several challenges with their existing noodle weighing and distribution system. The process required multiple operators...

Read the full Case Study