Gas Concentration Measurement

Antares Vision Group offers advanced in-line solutions for ensuring product integrity and food safety through precise, non-destructive gas analysis. Among these are the EVO-P and EVO-TRACE CO₂ systems—innovative technologies based on laser spectroscopy.

EVO-P monitors O₂ and CO₂ levels in sealed packaging to verify the correct modified atmosphere and assess product preservation, while EVO-TRACE CO₂ detects microbial contamination by measuring CO₂ variations in the container headspace. Together, they provide powerful tools for quality assurance, shelf-life optimisation, and process control across various food applications.

We can build our machines fully to retail specification.

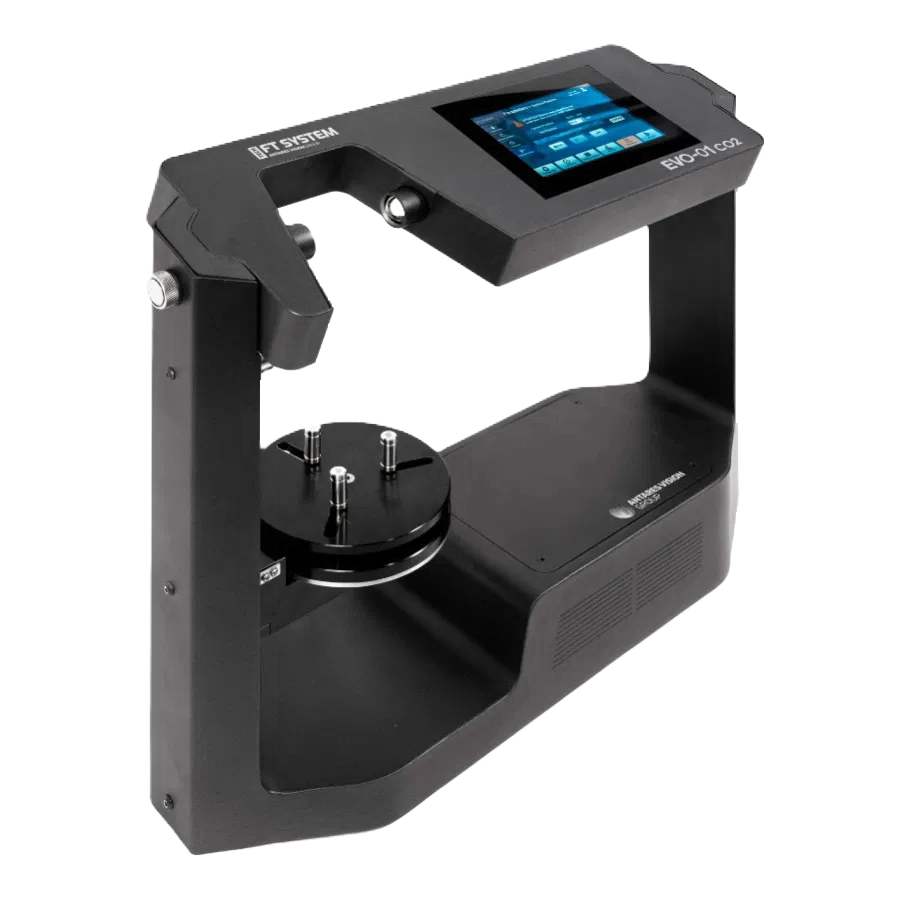

EVO Trace CO2

EVO-TRACE CO₂ is a laboratory instrument designed to detect microbial contamination by measuring trace levels of carbon dioxide in the headspace of sealed containers. Using non-destructive laser spectroscopy, it identifies CO₂ changes caused by microbial growth—particularly useful for products in quarantine or packaging not suitable for visual inspection. Ideal for dairy applications, EVO-TRACE CO₂ offers faster spoilage detection than traditional methods, with results possible within 24 hours at just 1 CFU/mL contamination.

Benefits:

- Ensures product safety by detecting the presence of microorganisms

- Repeatable measurements

- Laser spectroscopy-based

- Non-destructive method

- High reliability

- Fast and repeatable measurement

- Suitable for all bottle closures

- No consumables or wear parts

- Automatic measurement of product temperature

O2 / CO2 non-destructive analyzer – EVO P

EVO-P is a non-destructive gas analyser that measures oxygen (O₂) and carbon dioxide (CO₂) levels inside sealed food packaging using advanced laser spectroscopy. It accurately verifies gas concentrations in MAP (Modified Atmosphere Packaging) products, ensuring optimal conditions for shelf-life and quality. EVO-P helps detect packaging issues or oxygen presence that may affect flavour or preservation and allows repeated testing over time—ideal for evaluating gas-food interaction, especially with sustainable packaging changes.

Benefits:

- Guarantee the correct mixture of gas inside the packaging for MAP product

- Evaluation of gas-food interaction during the shelf life of the product

- Increase the number of analyzable samples for repeatable measurement

- Non-destructive method-sustainability increase

- No variability in measurements due to the operator

- Accurate evaluation of the effects on food in case of a change of type of packaging, i.e. sustainable

- Laser spectroscopy based

- Non-destructive analyzer

- Suitable for all sealed packaging (bags and trays)

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

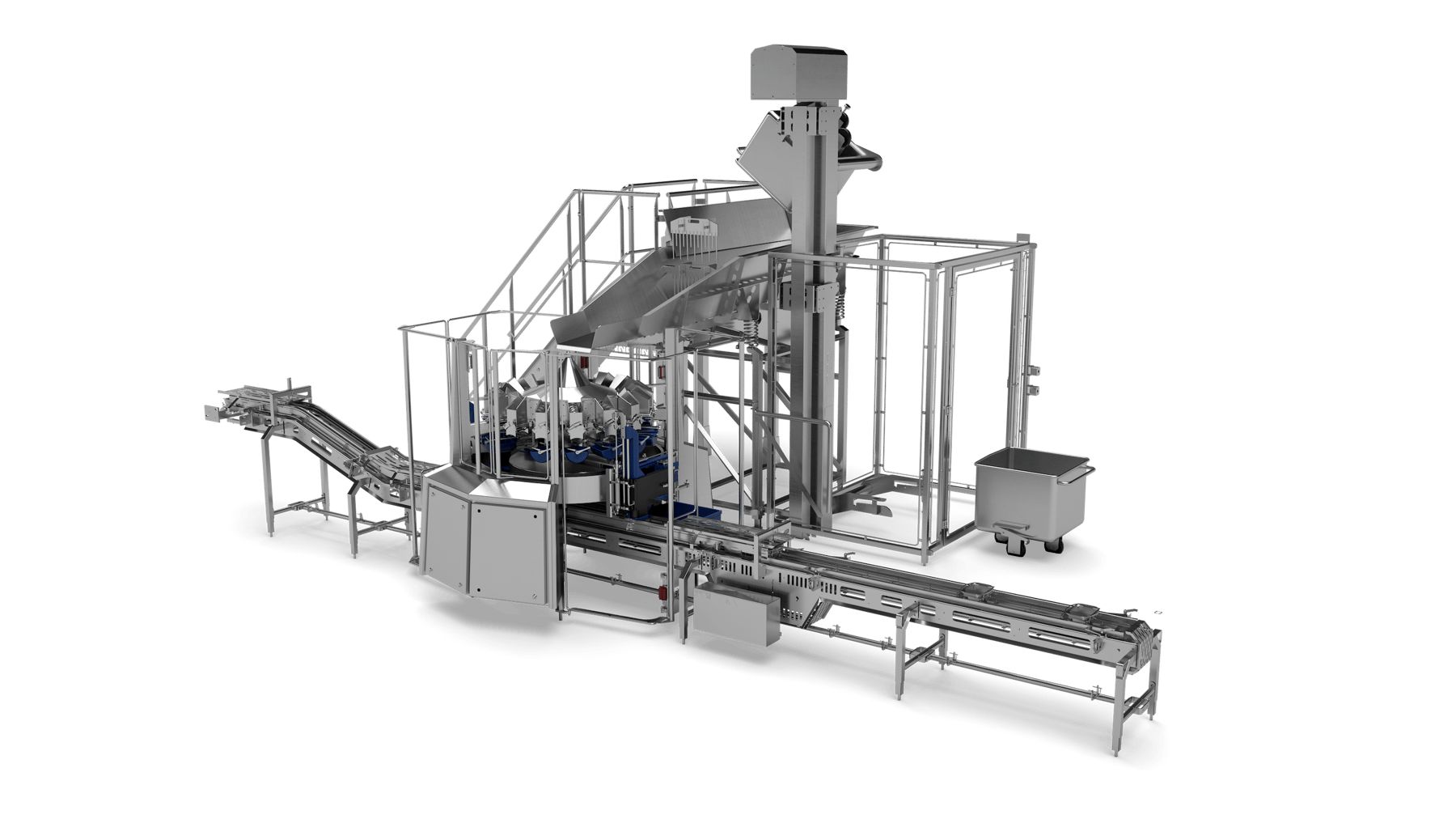

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.