Serialisation

Antares Vision Group offers a comprehensive range of advanced serialization and vision inspection systems designed specifically for the food industry. These solutions include the Print & Check systems for in-line code printing and verification on both flat packages and cylindrical containers, as well as high-precision vision systems for detecting serial codes in any orientation and linking multiple codes on a single product.

Together, they support full traceability, compliance, and quality control—enhancing supply chain transparency, protecting against counterfeiting, and preserving packaging design with invisible UV code options. We can build our machines fully to retail specification.

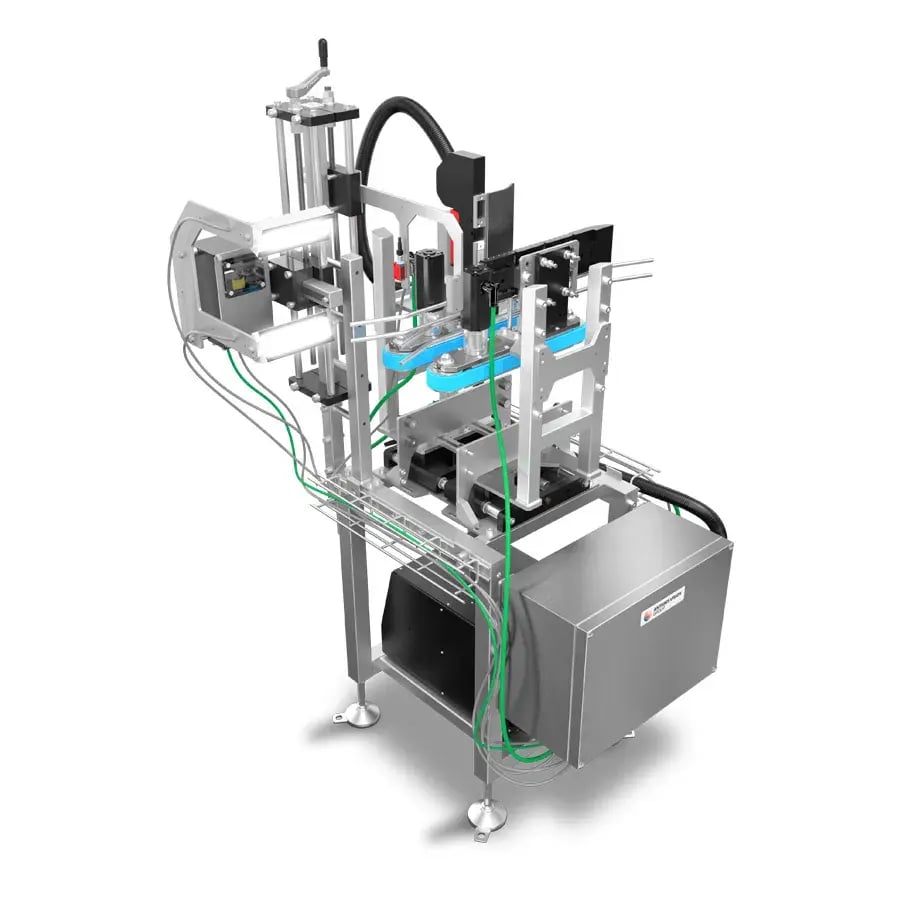

Print & Check for Serialisation on the Upper Side

The Print & Check system enables in-line serialization in the food sector by printing and verifying unique codes on bottle caps or container tops. This is the first step in assigning a digital identity to each product, ensuring traceability, quality, and compliance across the entire supply chain—from production to regulatory oversight.

An integrated printer applies the serial code directly onto the product, or a pre-printed label can be used. A high-resolution camera checks the accuracy of each code in real time, removing any non-compliant items. The data is stored for aggregation in secondary packaging like bundles or pallets, improving efficiency, reducing errors, and protecting against counterfeiting and grey market distribution.

Inspections:

-

Assignment of a unique digital identity to each sales unit

-

Verification of serial code integrity

-

Readability check on each unit

-

Validation of code uniqueness and accuracy

Print & Check for Serialisation on the Side

Designed for the food industry, the Print & Check system prints and verifies unique identification codes on the side of each package, creating a secure digital identity for every unit. This supports robust traceability, quality control, and compliance from production through to distribution and regulatory checks.

The system uses an in-line printer or pre-printed labels, with a built-in camera verifying code accuracy instantly. Any errors trigger automatic rejection, and the collected data feeds into later packaging stages. By minimising errors, preventing unauthorised distribution, and enabling full unit-level tracking, the system enhances productivity, strengthens consumer trust, and adds strategic value to food producers.

Inspections:

Serial Code Verification on the Body of Non-Oriented Vertical Products

This advanced vision system is designed to detect and read serial codes printed on cylindrical containers—like bottles and tubes—regardless of their orientation. Six side-mounted cameras capture the entire surface, ensuring accurate code recognition even when items enter the machine in random positions. The system stores each code for full traceability across production, distribution, and quality control.

Captured data feeds into the aggregation phase, linking individual units to secondary packaging (e.g. bundles or cartons) with a unique parent-child code structure. Compatible with laser, inkjet, and UV printing, the system also supports invisible UV codes, verified using special cameras and lighting—preserving packaging design while ensuring reliable traceability.

Benefits:

In-Line Control and Correlation of Serial Codes Applied to the Body and Cans

This advanced vision system links a primary serial code on the body of a bottle with an auxiliary code on the cap, ensuring full traceability through production, distribution, and regulatory checks. A dual inspection module handles the process: six side cameras read the main body code regardless of orientation, while a top-mounted camera verifies the auxiliary code.

Both codes are paired and stored in a database, enabling accurate identification during later stages such as aggregation. When bottles are placed into secondary packaging, the system reads the top-facing auxiliary codes while maintaining the link to their corresponding main codes. Compatible with laser, inkjet, and UV printing—including invisible UV codes verified by specialised cameras—the system ensures reliable, discreet, and design-friendly traceability.

Benefits:

- Integrity and readability check of codes, both on the body and the cap

- Verification of uniqueness and correctness of serialized codes

- Correlation between main code (label) and auxiliary code (cap), with saving in the database

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

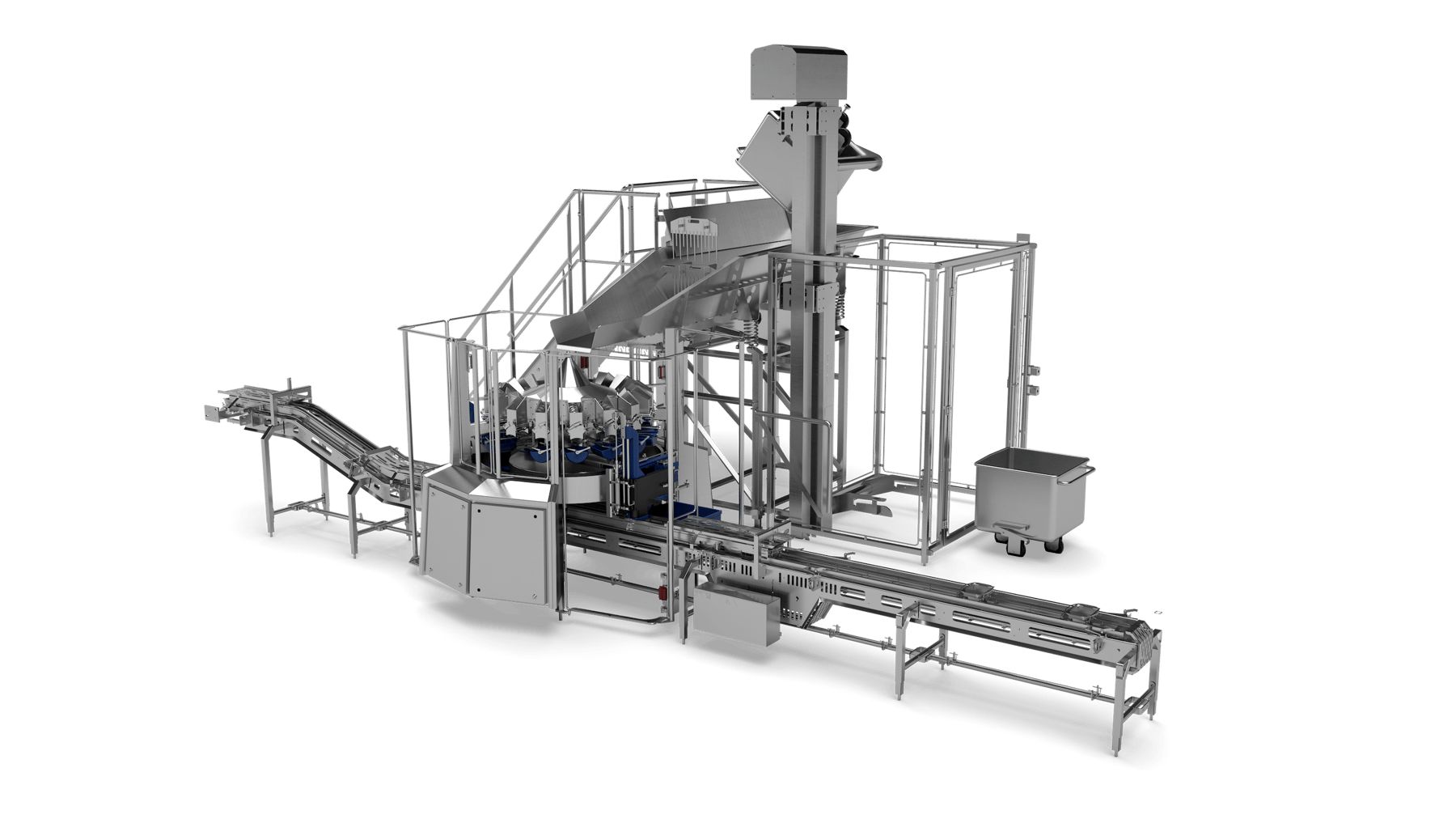

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.