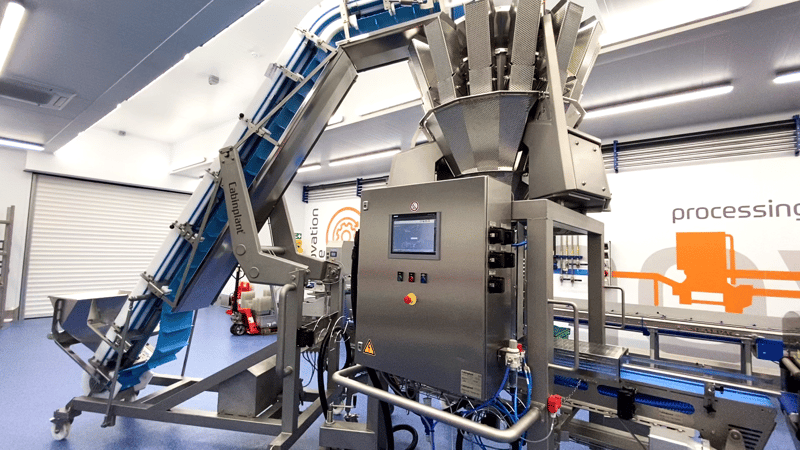

Designed with flexibility at its core, the Cabinplant Flexi-Line adapts seamlessly to both premade trays and thermoformers. This mobile weighing and packing solution is ideal for small batch producers and smaller enterprises looking to automate and scale. Easy to integrate into existing setups, it combines efficient product handling with the precision of our advanced Multihead Weigher—boosting accuracy, reducing giveaway, and streamlining your entire production process. With Flexi-Line, stepping into automation is simpler, smarter, and more efficient than ever.

High speed weighing and batching

As part of our full line solution, Sealpac UK & Partners offer multihead weighing and batching capabilities courtesy of Cabinplant.

To provide our customers with weighing and batching capabilities, we are proud to have partnered with Cabinplant whose class-leading multihead weighing and batching technologies are based on decades of knowledge and experience. From multihead weighing to multibatch distributing, we are able to offer a range of solutions that will help to optimise your production lines with increased accuracy and greatly reduced waste and give-away. These highly developed products can handle products from fresh meat, poultry and seafood to even the stickiest of products including marinated proteins, pasta and noodles.

Any speed with any product

From single to multiple channel weighing systems, our weighers are developed to suit all products from dry free flowing to fresh sticky.

Excellent Weighing Accuracy

The high-tech systems offer fantastic accuracy with greatly reduced give-away increasing efficiency and profit along with great presentation.

Minimum maintenance and easy cleaning

All our systems are designed to withstand washdown in a food factory. Simple design allows easy changeovers and cleaning. The combined benefits give you speed and flexibility.

Fast return on investment

The high portion rate combined with minimum maintenance means you’ll experience less downtime and more productivity thus demonstrating ROI quickly.

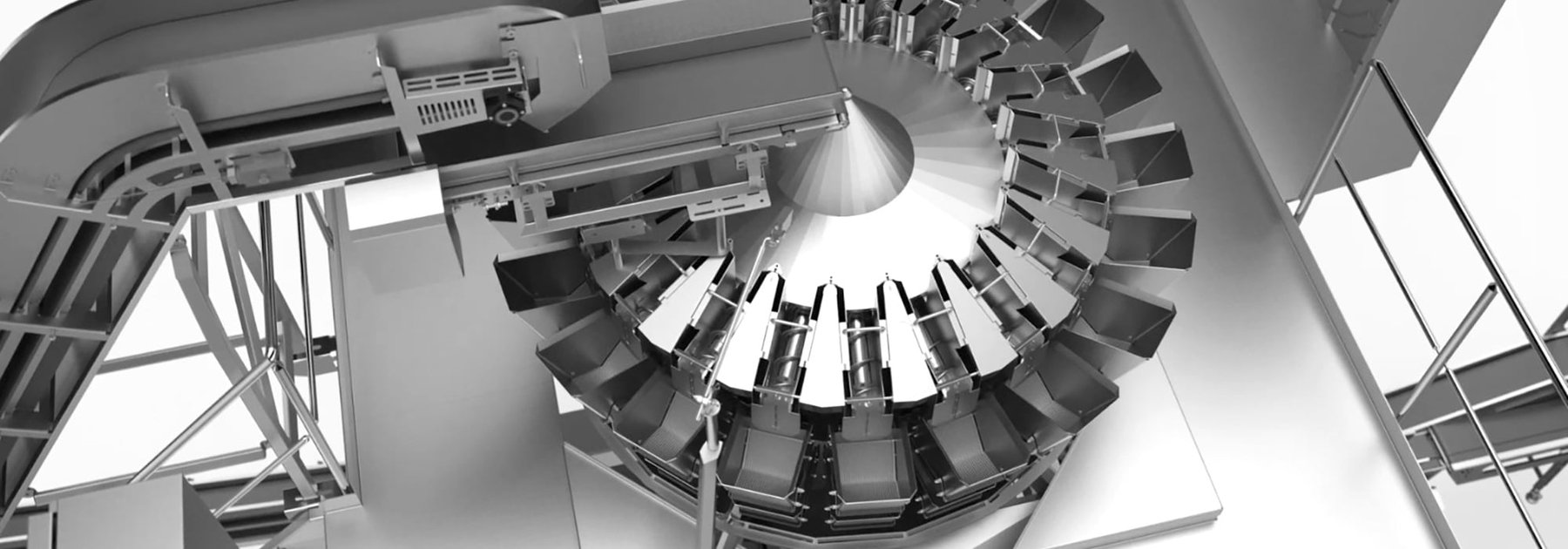

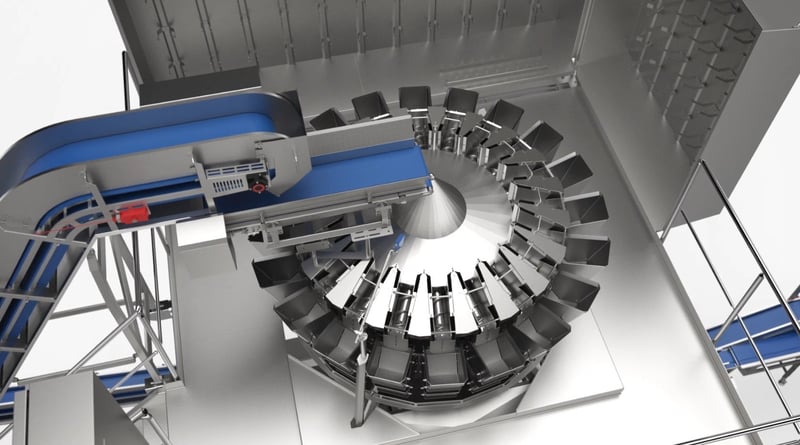

Multihead weighing solutions

Whether screw-fed or vibratory fed, multihead weighers are designed to meet the increasing demands of precision and speed during the weighing process of difficult products. They are available in a wide range of models, so we can meet your production line demands, perfectly configured to give optimal weighing, mixing and accuracy, even with the most difficult to handle products. They are also extremely reliable and robust, ensuring that there is minimal risk of breakdown, especially when paired with a tailored service contract.

Find out more

Flexi-Line Weigher

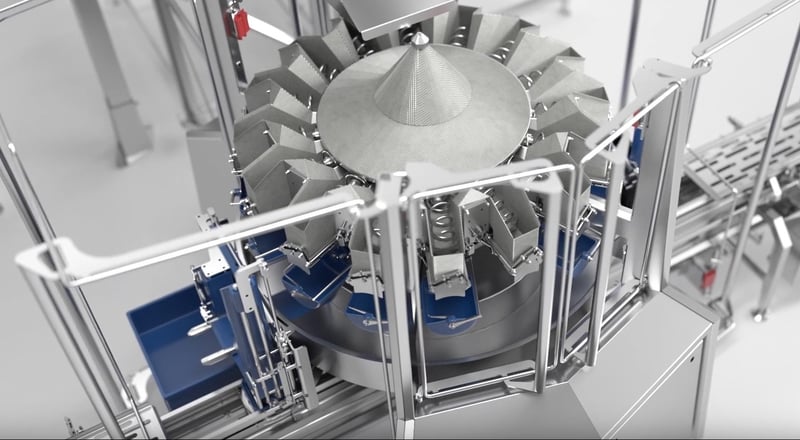

Multihead Weigher SF Extreme

Cabinplant's Multihead weigher SF Extreme is a highly efficient weighing solution, excelling in precision weighing of tricky items like mixed salads, coleslaw, and tuna flakes. Its advanced combinatorial weighing ensures accuracy in complex tasks, reducing manual handling and labour costs by up to 70% when integrated into your production line. This not only boosts efficiency but also enhances food safety by minimizing human contamination risks. With a compact height of 1,750 mm, it boasts one of the smallest footprints in the market for Multihead Weighers (MHWs), allowing easy placement in any production hall without height-related building restrictions.

Weighing and batching

Custom-designed for your exact requirements, our weighing and batching solutions offer high-speed accuracy, perfect for optimising the cost of production and reducing give-away. Designed to combine high volume with low waste, they can be configured for stand-alone use or as part of a complete line, making them a hugely flexible solution that will give you great ROI in either kind of environment. We can work with you to design a tailor-made solution to meet your individual requirements and specifications.

Find out more

In-line marinade

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Automating Skewer Production with the MIVEG 7200

The Challenge A major UK food manufacturer faced growing pressure to scale up its BBQ skewer production. Their existing line relied heavily on manual...

Read the full Case Study

-

Case Study

Installing A High-Speed Salad Layering Line With Sealpac UK and Partners

The Challenge A customer had recently taken on the production of layered salad and pasta products from another supplier. These were complex and tricky...

Read the full Case Study

-

Case Study

Automating Noodle Weighing and Distribution

The Challenge The customer faced several challenges with their existing noodle weighing and distribution system. The process required multiple operators...

Read the full Case Study

-

Case Study

From Manual to Precision – Automating Rice Depositing with Sealpac UK & Partners

The Challenge Our Product Manager - Gary Tufnell and Sales Manager - Tom Hughes approached a leading food manufacturer, who had a persistent problem:...

Read the full Case Study