Food Packaging

As part of our full line solution, Sealpac UK & Partners offer a range of packaging machinery from our partners.

Features and benefits

Flexibility

Reliability

Easy integration

Best practice

Traysealer

German-built SEALPAC Amax Traysealers are of exceptional quality, delivering reliable and high-efficiency performance all day, every day. Interchangeable tooling makes these tray sealers incredibly versatile, and suitable across many different sectors and food packaging applications, including MAP, vacuum, Skin and many others.

Thermoformer

Find out more

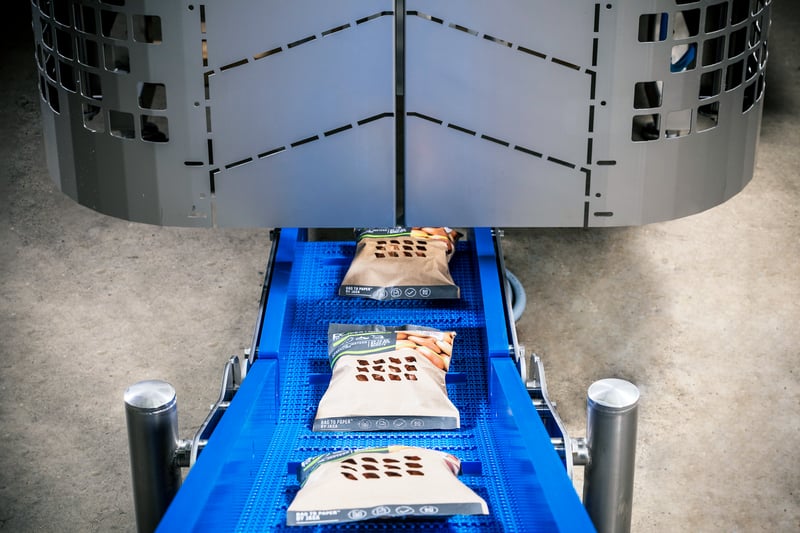

Bagmaker

Our range of Bagmakers offer flexibility and reliability to suit all types of bag styles. Our consultants, with practical application knowledge work with you to deliver the best machinery and additional equipment to integrate in to your production line. Bag styles include pillow, block bottom, gusseted, quattroseal, doy pack, etc.

Find out more

Flowrapper

Automatic wrapping, manufactured for wrapping fresh products with or without support or tray, automatically with heat-sealing materials. The process can be adapted for multiple materials such as BOPP, polyolefin, complex and complex shrink films, biodegradable and compostable materials and paper. With film unwinding from the top or the bottom and the possibility of working with MAP (modified atmosphere packing) if required.

Find out more

Vacuum packaging

Choose from a range of manual and automatic vacuum packing solutions, suitable for a variety of product types. Whether you're looking for a high-output solution for retail production, or whether you're a small business looking to facilitate local deliveries, we can cater for all types of efficiency requirements.

Find out more

Sleevers

Browse from a collection of sleevers that are fast, compact, and easy to operate, processing up to 100 trays per minute with change-over times under five minutes. Its hygienic, plug-and-play design integrates seamlessly into existing packaging lines, with options for one or two conveyor belts, a bypass or ejection station, and a label applicator. It’s perfect for enhancing efficiency while allowing continued use of your current trays.

Find out more

Packaging applications

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Automating Skewer Production with the MIVEG 7200

The Challenge A major UK food manufacturer faced growing pressure to scale up its BBQ skewer production. Their existing line relied heavily on manual...

Read the full Case Study

-

Case Study

Installing A High-Speed Salad Layering Line With Sealpac UK and Partners

The Challenge A customer had recently taken on the production of layered salad and pasta products from another supplier. These were complex and tricky...

Read the full Case Study

-

Case Study

Automating Noodle Weighing and Distribution

The Challenge The customer faced several challenges with their existing noodle weighing and distribution system. The process required multiple operators...

Read the full Case Study

-

Case Study

From Manual to Precision – Automating Rice Depositing with Sealpac UK & Partners

The Challenge Our Product Manager - Gary Tufnell and Sales Manager - Tom Hughes approached a leading food manufacturer, who had a persistent problem:...

Read the full Case Study