Product Inspection Systems

Inspection before packaging plays a vital role in maintaining product quality, food safety, and process efficiency. By checking for defects, abnormalities, or inconsistencies early in the line, these systems prevent unsuitable products from reaching the packaging stage. This reduces waste, minimises the risk of recalls, and ensures only the right products move forward — protecting both your brand and your bottom line.

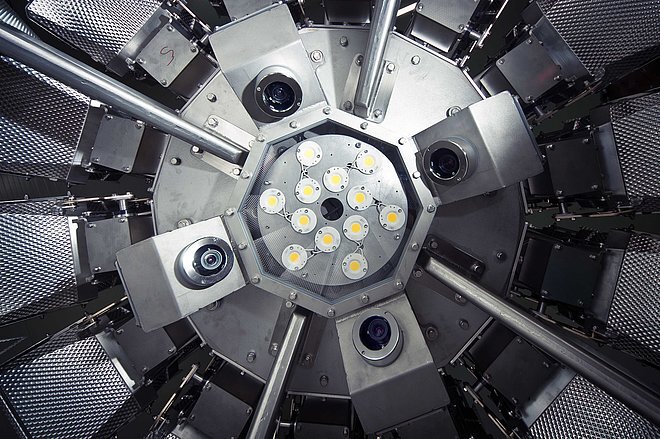

MultiCheck

MultiCheck is a compact, space-saving inspection solution designed for seamless integration into multihead weighers. Positioned directly above the product flow, it provides a clear view of falling goods without any contact, ensuring reliable detection of foreign bodies such as plastics or other materials. Built with robust housings to withstand harsh hygiene conditions, the system communicates in real time with the machine control to trigger immediate ejection or stoppage. Operators benefit from clear visual feedback of detected items and access to detailed statistics, helping maintain the highest levels of product safety and efficiency.

-

Camera system housing made of V4A stainless steel in IP69-like protection class.

-

Compact control cabinet in IP69 protection class for high-performance computers and electronics.

-

The system is individually adapted to the multihead weigher.

-

Hygienic cable routing is possible.

-

Scratch-resistant acrylic or makrolon windows in front of the cameras for long-lasting clarity and easy maintenance.

-

Operating at temperatures from -18 °C to +30 °C is possible. Intelligent flash control ensures uninterrupted operation even in direct proximity to products.

ChickenCheck

Harnessing advanced camera-based inspection, ChickenCheck delivers continuous, non-contact evaluation of poultry during processing. It precisely detects and classifies physical issues—such as footpad lesions, joint injuries, catch damage, ascites, dermatitis, and even anatomical features like weight and breast skin condition. The system operates at high throughput (e.g., up to 18,000 birds per hour), integrates seamlessly with production lines, stores annotated image data, and automatically generates daily batch reports for full traceability.

- Highly efficient evaluation with database connectivity

- Customizable to individual needs

- Capture unit with lighting, protected for harsh environments

- Detailed automatic reporting

- Autonomous inspection & warning system for system conditions

- 100% inspection

- Optional: Automatic generation of daily reports & integration of reports on tablet/smartphone

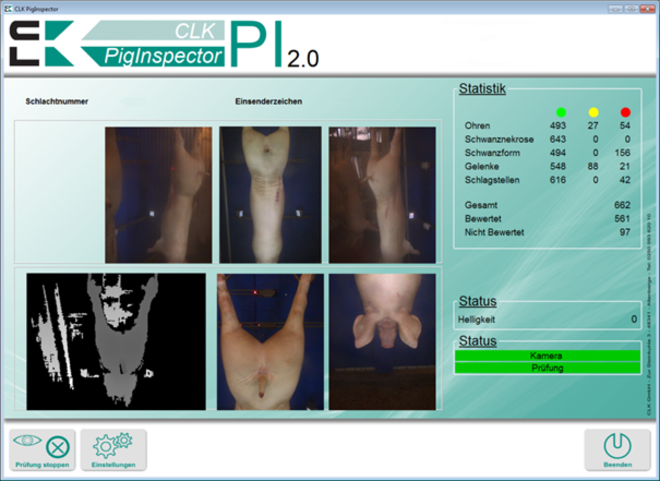

PigInspector

PigInspector employs advanced 2D and 3D imaging to automatically evaluate pig carcasses in real time, focusing on animal welfare indicators such as ear necrosis, tail tip necrosis, joint decubitus, tail length, and trail marks. Integrated into production lines, it enables continuous, non-contact inspection that filters out affected carcasses before they proceed further. The system enhances meat quality while reducing evaluation costs and supports traceability and compliance through robust documentation and analytics.

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

-

Case Study

Food safety – Inspection and detection

Automated food quality and safety inspection solutions The Challenge The presence of micro-holes in food packaging is a particularly critical problem in...

Read the full Case Study