Sealpac UK & Partners excel in providing comprehensive end-to-end solutions. Our expertise ensures reliable design, installation, and maintenance of production lines across multiple industries. Challenge us – you'll be glad you did!

Find out what your journey with us will look like!

Sealpac UK & Partners excel in providing comprehensive end-to-end solutions. Our expertise ensures reliable design, installation, and maintenance of production lines across multiple industries.

Find out what your journey with us will look like!

-

Consulting

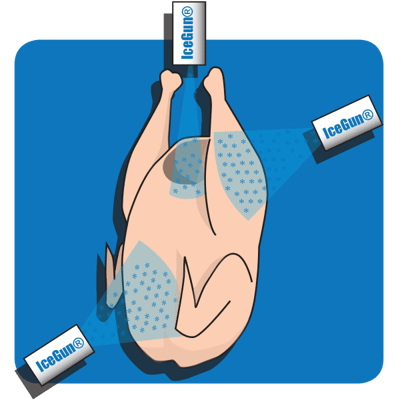

We’re proud of our proven track record providing bespoke automated production line solutions to all sectors in the food industry. With our engineering and industry knowledge and experience, along with project management expertise, our consultancy service has helped customers find food production solutions tailored exactly to their needs. Our team work hand in hand with you from start to finish, covering all sectors including meat, poultry, fish, seafood, dairy, ready meals, snacks, convenience, pet food and confectionary.

Find out more -

Delivering

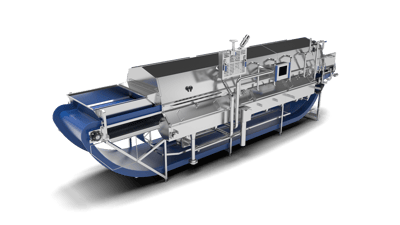

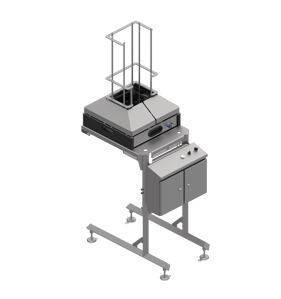

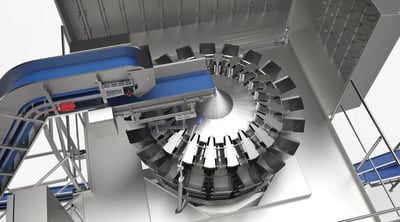

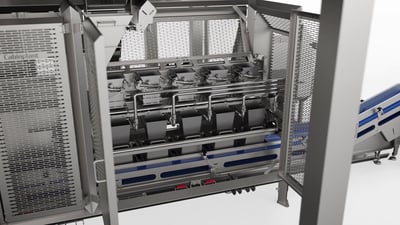

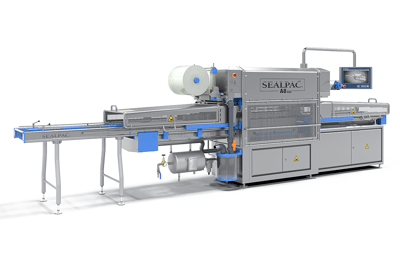

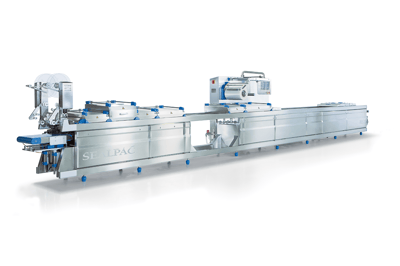

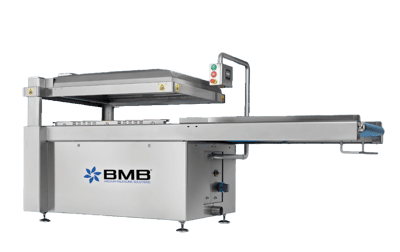

Our network of trusted partners have an impressive range of food production machinery including sorting, processing, weighing, depositing and packaging equipment. Packaging machinery includes Traysealers, Thermoformers, Bag Makers, flowrapping and vacuum packing. The end of line solutions take care of quality control including checkweighers, Xray, metal detection, and combinations with seal inspection and leak detection. Finally, the case packing and palletising solutions take care of automating your production line right up to the despatch door.

-

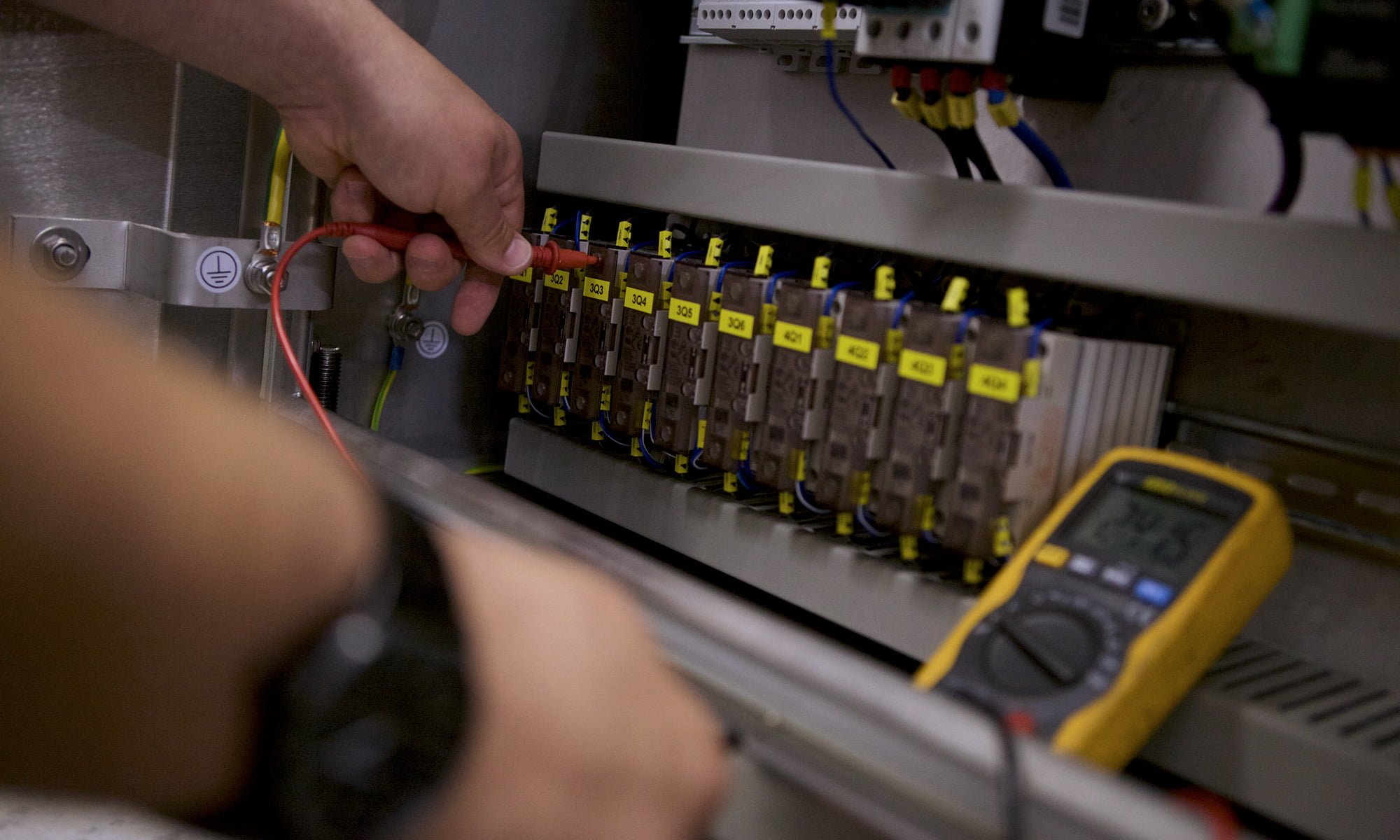

Supporting

We recognise the significant investment you make on your food production lines. That’s why our team of engineers are strategically placed in the UK and Ireland to be there when you need them. In addition, we stock a comprehensive range of spare parts in the warehouse, so you can order parts directly to your door. Our tailor made service contracts are designed to save you time, cost and keep you running efficiently and smoothly all year round. The engineering team is always on hand to provide technical support over the phone or where necessary, an emergency call out.

Our Expertise

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.

In partnership with

Consultancy services

Combining our knowledge and experience with best practice solutions and class leading food machinery technology.

Machinery solutions

Aftersales support

Class leading after sales covering the UK & Ireland including machine maintenance, production line optimising, training, upgrades and spares packages.

The latest from our blog

How to Choose Your Right Packaging Format?

In today’s competitive food industry, choosing the right packaging format is crucial—not only for product protection, but also for brand appeal, ...

Continue reading

IFFA 2025 – A Show to Remember for Sealpac UK & Partners

What a buzz IFFA 2025 turned out to be! From start to finish, it was one of the most exciting and successful exhibitions we've ever attended – and that’s...

Continue reading

Veganuary with Sealpac UK and Partners

As Veganuary continues to inspire consumers to explore plant-based lifestyles, businesses are globally adapting to meet the growing demand for vegan...

Continue reading

Do you have a project that you’d like to discuss?

Our experts are on hand to help maximise the efficiency of your line. Let’s see what we can do for you.

-

Case Study

From Manual to Precision – Automating Rice Depositing with Sealpac UK & Partners

The Challenge Our Product Manager - Gary Tufnell and Sales Manager - Tom Hughes approached a leading food manufacturer, who had a persistent problem:...

Read the full Case Study

-

Case Study

Assisting with Labour shortage by automating monotonous processes

The Challenge With a demanding production schedule and limited access to reliable short-term labour, this customer faced two major hurdles: keeping up...

Read the full Case Study

-

Case Study

Successfully Relocating Packaging Solutions To A New Site For A Poultry Processing Company

Relocating Packaging Solutions In A Poultry Processing Company The Challenge The challenge presented to us involved relocating three A series...

Read the full Case Study