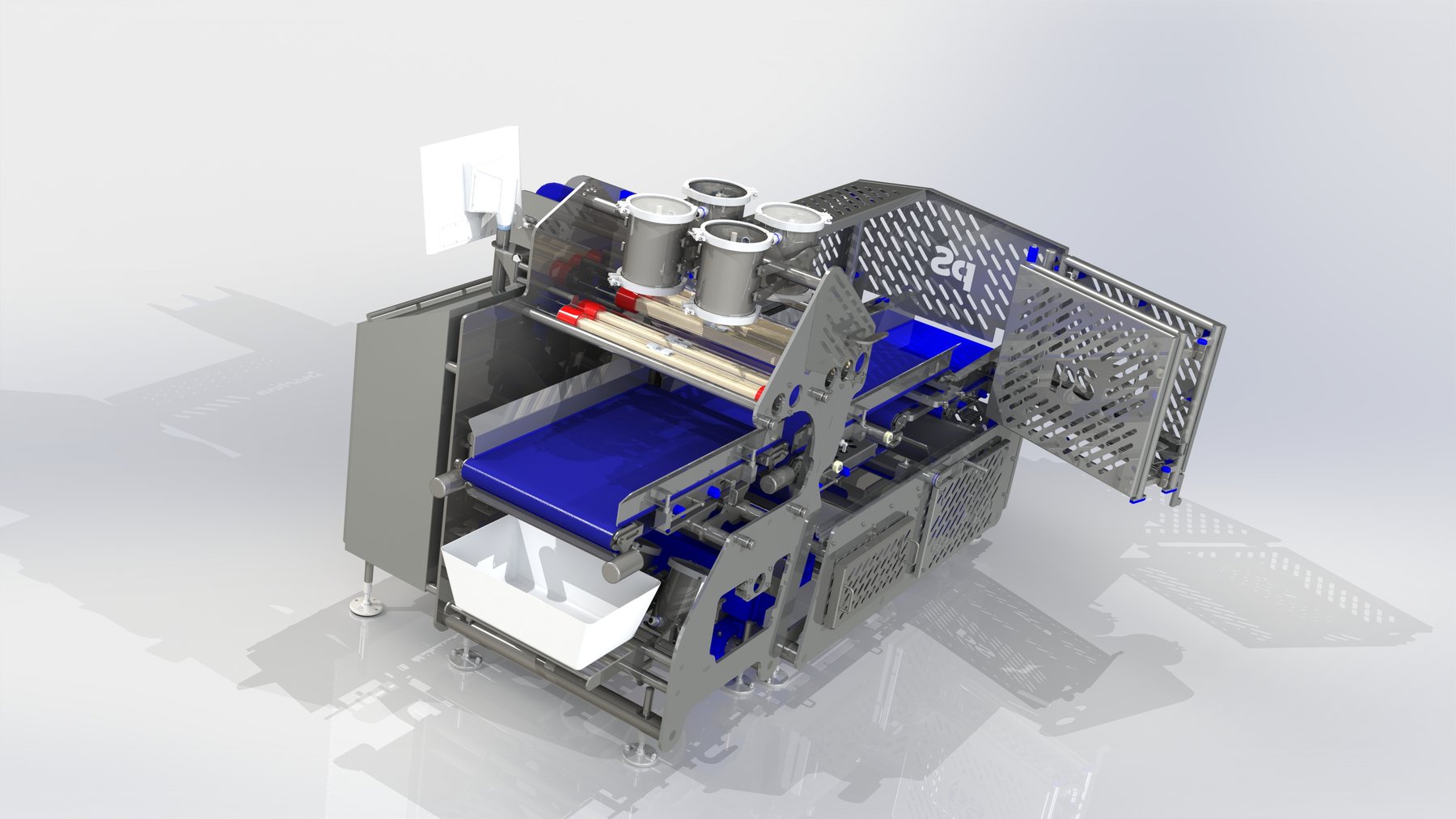

Foreign Material Inspection System

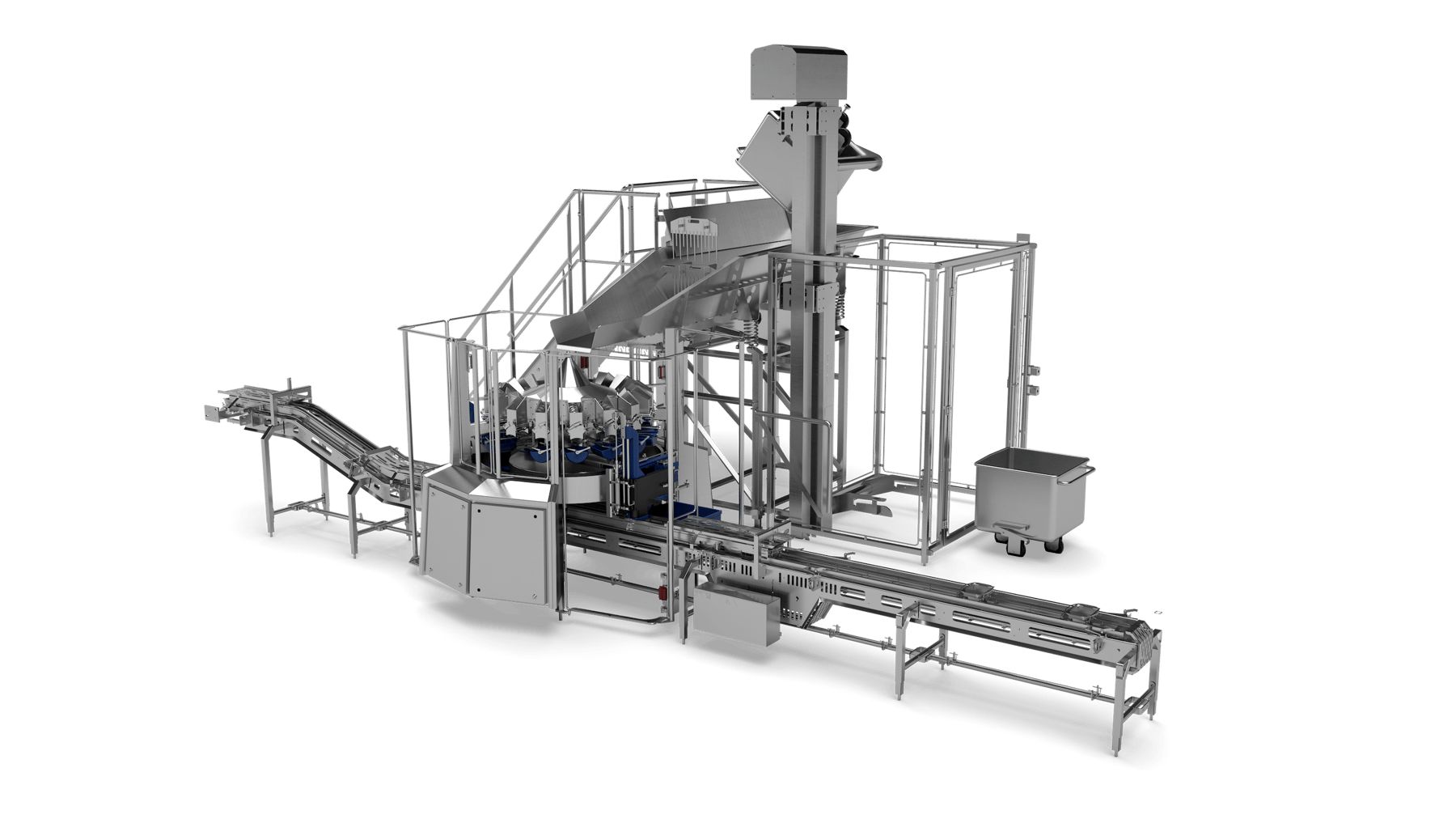

Low Density Foreign Material Detection and Removal Systems

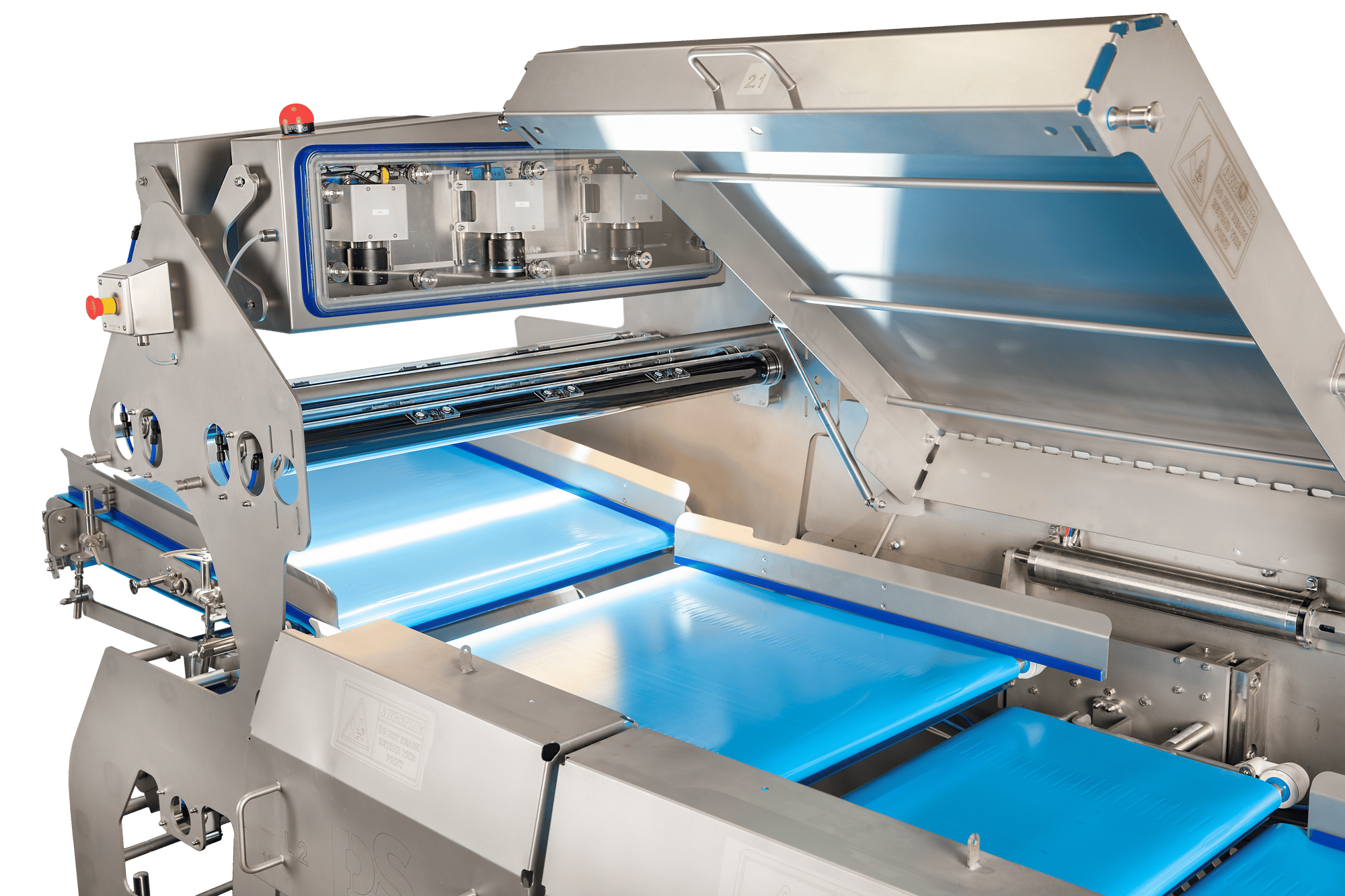

ProSpection's FMI system conducts simultaneous top and bottom inspections of products in vivid high-definition color. Defects are prominently marked in red by the system for rejection and subsequent quality control review. Featuring magnetic-driven motors, an advanced high-speed rejector, and effortless tool-less belt removal with seamless positive drive belting, these inspection systems ensure optimal performance. Additionally, remote monitoring functionality and real-time statistical reporting are included as standard features of the system.

Bacon Ends and Pieces FMI System

Diced Product FMI System

Arugula and Spinach FMI System

Beef FMI System

Cheese FMI System

|

INSPECT:

|

FEATURES:

|

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.