Raising efficiency and production

Raising efficiency and production

The Challenge

Between 400 & 500 tons of cheese move through the packaging and production facility.

Since the demand for sliced cheese was rising, our customer decided to invest in a new thermoformer line and needed a partner for reliability and total project capability.Flexibility was also key, as well as its existing 150g and 300g retail packs, the line also had to be capable of running 400g packs for larger households and 750g for the hotel, catering and restaurants.

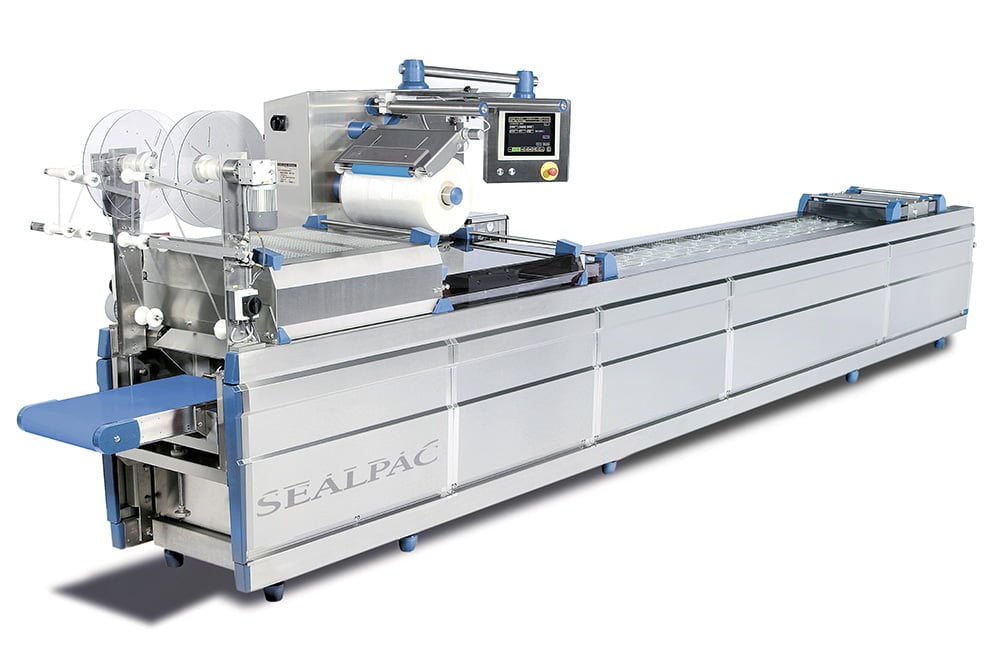

Our Solution – RE30 Thermoformer

The Seapac RE30 Thermoformer was placed at the heart of the line to create the wide variety of pack sizes. Cheese blocks are automatically sliced, weighed and transported to the packing area. The packs are sealed with a modified atmosphere extending the shelf life and then converged in to a labelling system and finally arrive at the case packing station.

Quality control is a top priority and managed by leak detection and splice detection to make sure every pack leaves with a quality assurance.

Results

Our customer was able to achieve higher outputs and short changeover times with a versatile machine that can handle various different types of packaging.

Furthermore, less staff are needed to operate and supervise the line, which means a benefit from labour savings too.