Reducing downtime and increasing yield

The Challenge

A leading European meat and poultry processor had the challenge of delivering a wide variety of marinated products in small batches to supermarkets. This project required a high degree of weighing accuracy and quick changeovers whilst maintaining efficiency.

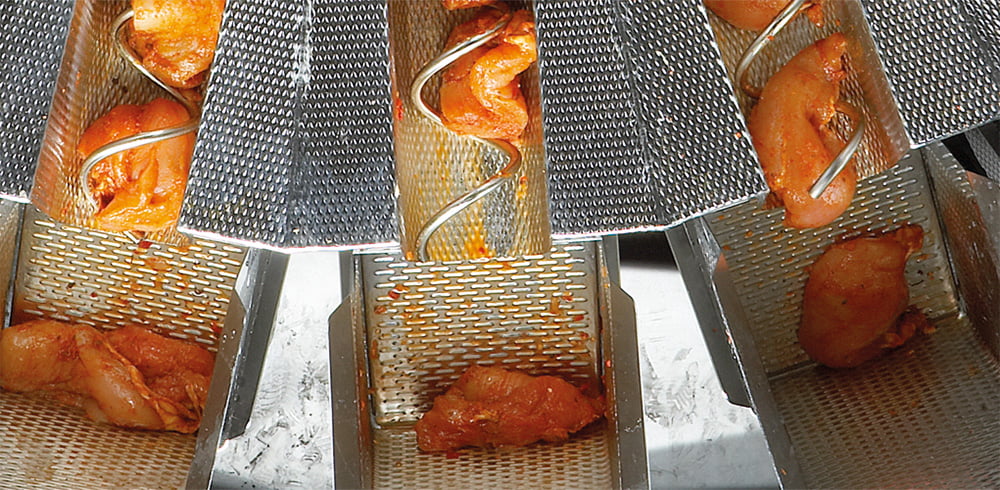

Our Solution — In Line Marinading

The Cabinplant marinating and batching solution was installed on several lines in two of their biggest facilities. Cabinplant don’t follow the traditional messy pre marinating process, as meat is marinated after weighing in accurate portions. This reduces the washdown and changeover time with less parts needing cleaning.

Marinade volume is automatically balanced to match each portion, which makes pack weight more consistent. Using the new Cabinplant system, changeover times dropped from 45 minutes to just 15.

Results

Each line now produces 40-50 portions a minute, and the meat processor achieved an 80% faster cleaning and changeover process.