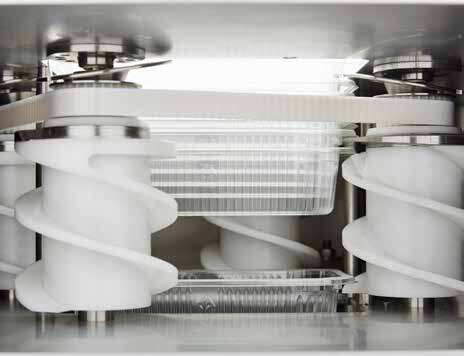

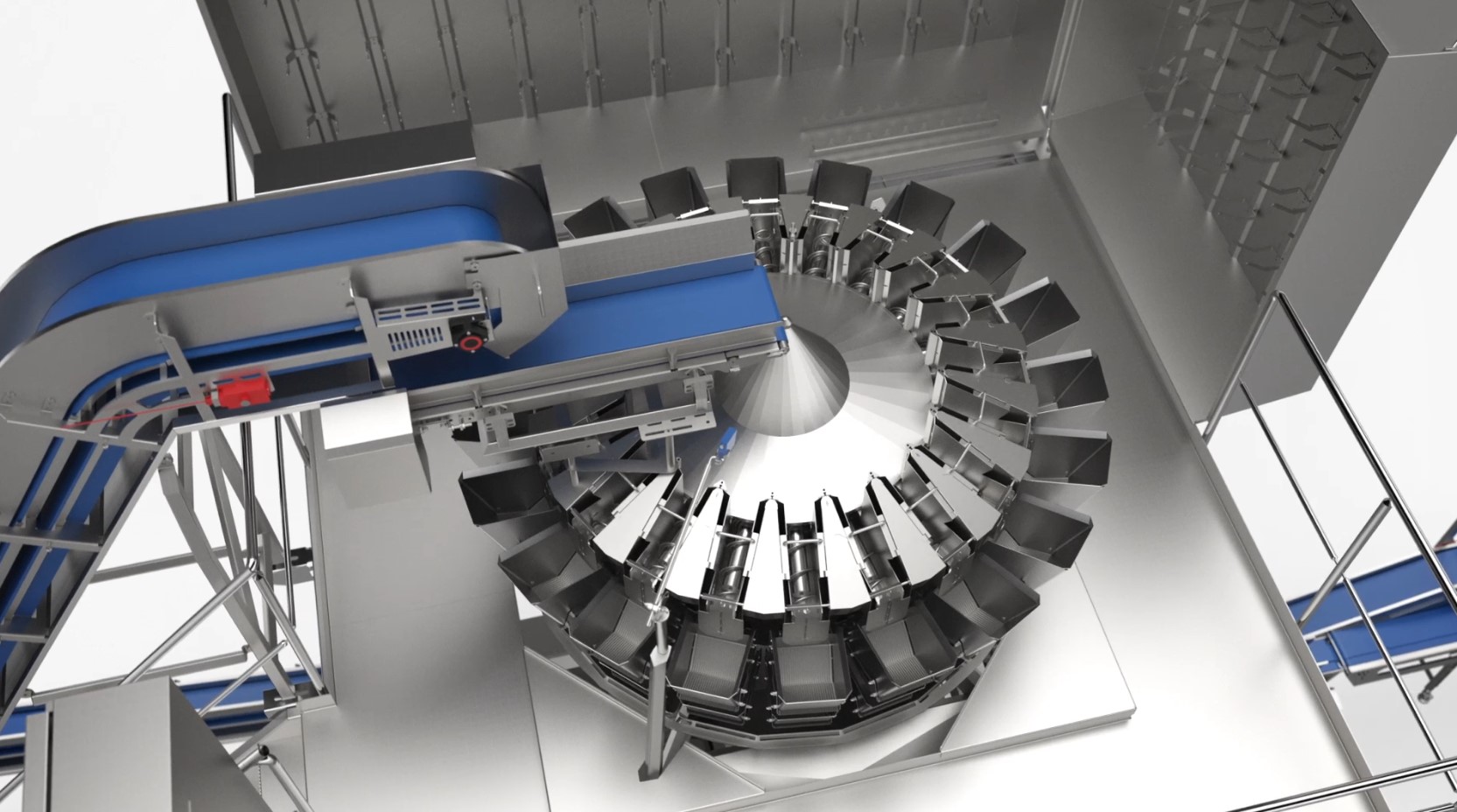

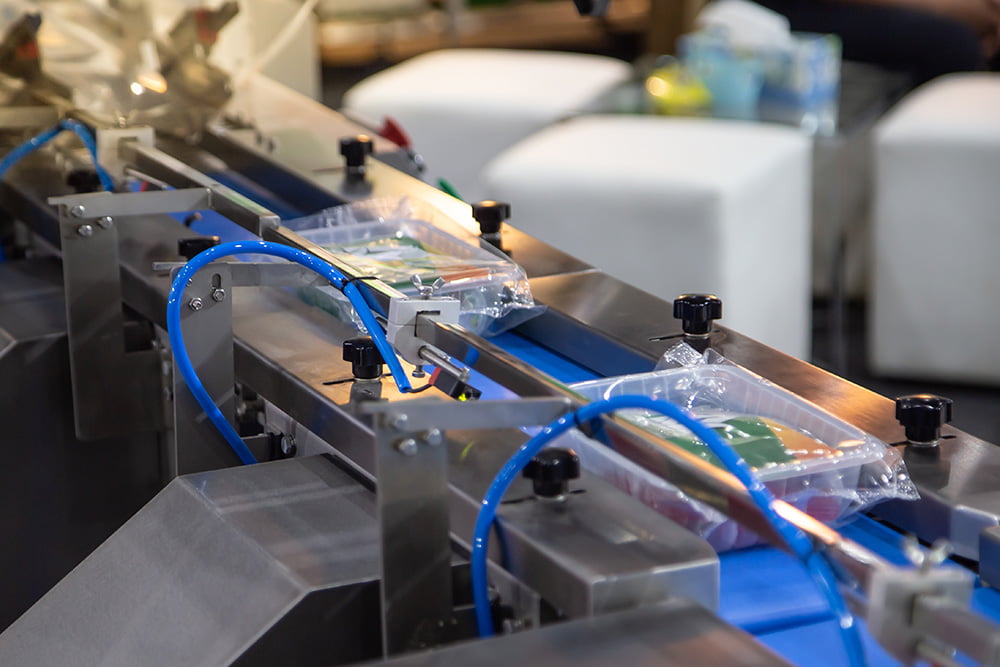

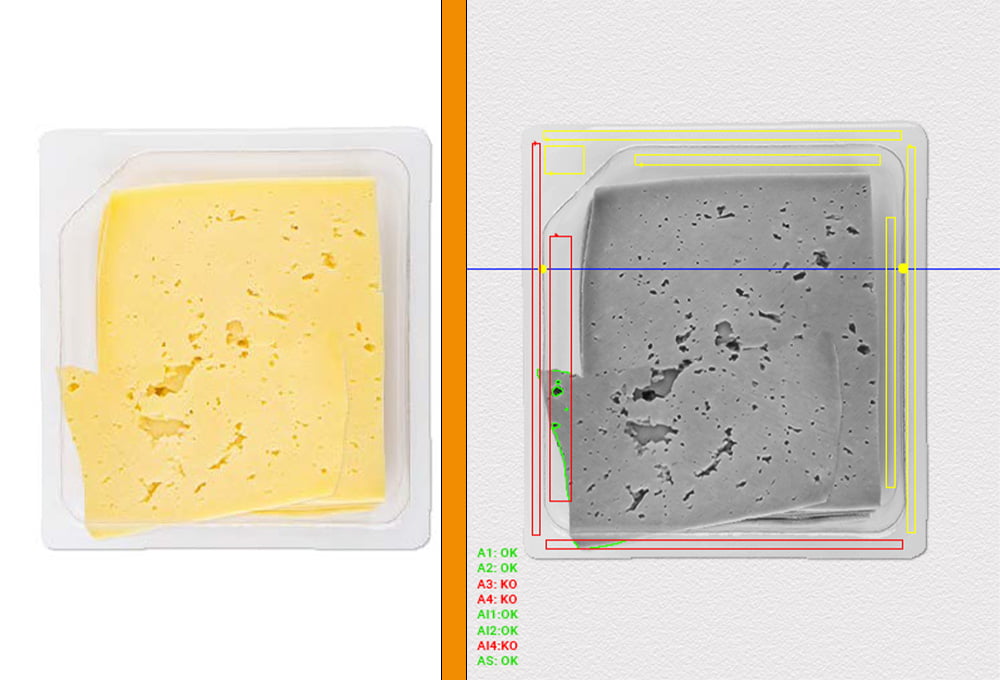

Machinery solutions

We are the leading supplier of full-line solutions within the UK, covering every aspect of production from start to finish. Whatever your line requirements, we have the right machines for the job and the experience in how to maximise your line efficiency.

Solutions for every stage of the line

Do you have a project that you’d like to discuss?

Our experts are on hand to help maximise the efficiency of your line. Let’s see what we can do for you.