Pallet freezer spacers are devices used in cold storage warehouses to ensure better air circulation around products, which speeds up the cooling process and maintains a uniform temperature. The use of quality spacers during freezing in food processing can increase energy efficiency, improve safety, enhance product quality, and optimize space utilisation.

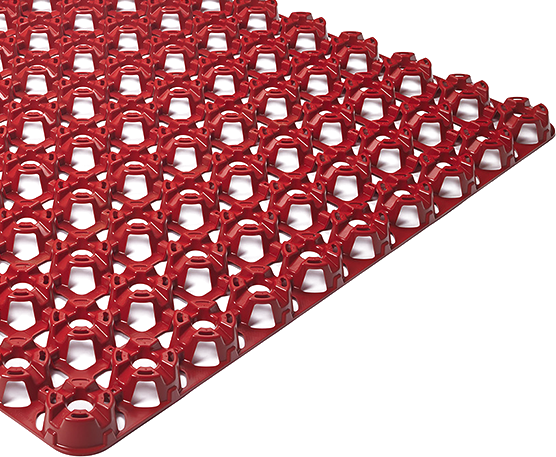

There are several types of pallet freezer spacers, and their use depends on the specific needs and constraints of the warehouse. The main types include plastic, aluminium, slotted and stackable freezer spacers. There are also freezer spacers that are custom made according to the specific needs of the warehouse. Among these, plastic freezer spacers are among the most common types of spacers. They're made from durable and lightweight plastic materials that can withstand very low temperatures. The design usually consists of interconnected beams forming a grid-like structure, allowing cold air to flow through the spaces.

The choice of freezer spacer would depend on various factors including the type of product, the desired freezing or thawing rate, the available space, and budget considerations. At Sealpac UK, we work with Plastic Frost to provide our clients with the Optiflow Freezer Spacer, a revolutionary design that helps to evenly distribute temperature-controlled air between stacked cartons, with optimised air flow, shape stability, durability, and hygiene.

Choosing the right, quality-tested pallet plays a crucial role in food processing. However, the specific benefits can depend on factors such as the type of food being processed, the freezing method used, and the design of the spacers.

Some of these include:

- Uniform Freezing: Spacers allow for better air circulation around the product, which leads to more uniform freezing. If a spacer is not of good quality, parts of the spacer can collapse after a few uses, restricting the air circulation in these areas. This is a key concern because uneven freezing can lead to variations in product quality. For instance, parts of the product that freeze slower might have a different texture or flavour compared to parts that freeze faster.

- Faster Freezing: Improved air circulation also means that the product freezes faster. This is beneficial because faster freezing leads to the formation of smaller ice crystals, which cause less damage to the cellular structure of the food. As a result, the food retains its original texture and flavour better when it is thawed. With Optiflow freezer spacers, you can get 40% time saving/turnover increase compared to

the current freezer spacers. This faster freezing reduces the time the food spends in the "danger zone" temperature range where harmful bacteria can multiply. This makes the food safer to consume. - Energy Efficiency: By enabling faster and more uniform freezing throughout every use, spacers of good quality can increase the energy efficiency of the freezing process. This can lead to cost savings and is also better for the environment. Choosing the Optiflow freezer spacer not only results in a 26% reduction in energy consumption compared to conventional freezer spacers but also contributes to lower water usage, with only 0.2 liters per spacer required for cleaning.

- Reusability: Reusability is a key advantage when comparing low-quality plastic freezers to the Optiflow freezer spacer. Low-quality plastic spacers tend to have poor durability, often collapsing after just one or two uses. In contrast, the Optiflow freezer spacer offers remarkable durability, significantly reducing the likelihood of collapse. Additionally, you can wash and reuse these spacers multiple times, making them a cost-effective choice for many warehouses seeking to cut expenses.

- Stackability: Good quality spacers can provide structural support, throughout a long period of time, that allows products to be stacked during the freezing process, maximizing the use of space in the freezer. The sturdy build of the Optiflow Freezer spacer enables secure and efficient stacking, even at extreme temperatures ranging from -60°C to +80°C. These spacers exhibit impressive resistance to shocks and impacts, with a substantial load-bearing capacity of approximately 7500 kg. Their generous load surface area ensures that packages stay level, promoting optimal airflow throughout the freezer.

Difference between a low quality freezer spacer (left) and the Optiflow Freezer Spacer (right).

At Sealpac UK, we offer automated palletizing solutions that seamlessly integrate with your freezer spacers, ensuring the safe and efficient transition of your products from the food production line to the supermarket. Our capabilities encompass a range of processes, including pallet layer formation, palletizing and depalletizing, layer scanning, and the preparation of fully finished pallets for transportation. This includes wrapping, weighing, labeling, and strapping, all designed to meet your specific needs.