We are very proud of the close working relationships we form with our customers - some of whom have been with us for over a decade! This level of personalised care and attention is reflected in our service contracts.

Proactive maintenance sits at the heart of all SEALPAC UK service contracts - which means we solve problems before they even occur. The result being less downtime, less disruption and complete peace of mind for our customers. But those aren’t the only benefits.

How does a service contract work?

Each service contract is tailored to an individual customer’s needs and preferences and will usually run for between 1-3 years, depending on factors such as machine usage levels.

The contract includes all parts and labour to service the four main areas of the machine; lift, linear, film and MAP/Skin systems. There are several bespoke elements that may be included, such as comprehensive training packages.

The contract includes all parts and labour to service the four main areas of the machine; lift, linear, film and MAP/Skin systems. There are several bespoke elements that may be included, such as comprehensive training packages.

Customers are looked after by our dedicated service contract team, who not only offer support over the phone or by email, but take part in the onboarding process, make onsite visits and will co-ordinate all aspects of the servicing, maintenance and training schedules.

Prevent issues before they arise

Regular servicing can ensure a machine continues to run at its optimal efficiency and that your return on investment is fully protected. Far from being a purely reactive service, jumping into action only when there’s a problem, it’s about preventing issues before they arise.

We know our customers cannot afford for a machine to be down for any amount of time, which is why we work proactively to inspect machines for parts that may soon be needed or are approaching their end of life. We also monitor usage trends and understand the cycles of individual parts. This type of predictive maintenance helps minimise downtime, so production lines are always up and running and OEE is enhanced.

Based on customer data, annual spending decreases by 23% with a service contract

The alternative to taking out a service contract is to pay for services, parts and labour as and when they are required. These would be charged at the standard list price.

This is where one of the greatest financial benefits can be seen. When you compare the total cost being spent by customers choosing this route to those with a service contract, annual spending decreases by 23% with a contract.

6 benefits to having a SEALPAC UK & Partners service contract

Here’s a quick guide to the top benefits:

- 90% less engineer call-outs

Engineer call-outs drop dramatically when service contracts are in place. This can be attributed to the regular servicing, proactive maintenance and the strength of the customer relationships being built. By knowing our customers, understanding their usage and the challenges they face, we can help them avoid unnecessary expenditure or drops in production. - 30% saving on labour costs

With a service contract, you avoid paying the fixed price for labour. For a typical customer this can lead to a saving in excess of 30%, compared to the ‘pay as you go’ alternative. - 20% less spent on spares

Another benefit of the predictive maintenance you receive with a service contract is a reduction in spending on spare parts, due to our advanced forward planning and technical scheduling expertise. Any parts needed will usually just be those included under the contract, along with planned maintenance, as opposed to ad-hoc services. - Improved OEE over time

Our customers tell us their OEE has been impacted on positively by having a service contract. Here’s what one manufacturer had to say:“Since mid-2016, we have implemented the SEALPAC UK preventative service package. A recent internal review carried out by ourselves has highlighted that the service costs have nearly been neutralised by the drop-in breakdown repair/parts costs. The impact on the business is that downtime on the machines has become minimal to insignificant.”- Existing Customer of 10 years - Comprehensive training

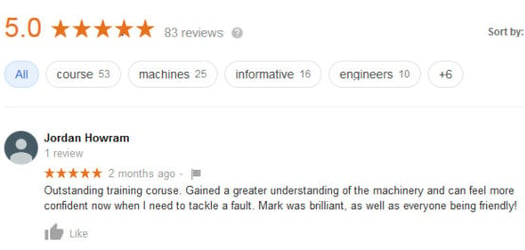

If a training plan is chosen to be included within a contract, then this can bring many added benefits. The training covers all skill levels, right up to super users. It means our engineers spend more time on site, where they can pass on even more tips and recommendations to help upskill in-house teams. Training is also available at SEALPAC UK’s base in Poole. - Free up in-house engineers

In-house engineering teams tell us that they often don’t have the resources needed to complete the service work required. By having an agreement in place, the pressure is taken off them and they can feel confident that the machine is in good hands. This allows them to concentrate on what they do best and the other areas of the business that need their skills and attention.

For a chat about how a service contract could benefit you, call us on 0845 302 3056.