The seafood industry in the United Kingdom stands at a phase where traditional methodologies intertwine with the advent of automation and artificial intelligence (AI). In recent years, the industry has witnessed a remarkable shift towards automated solutions to enhance efficiency, address labor challenges, and ensure sustainable practices. This article aims to explore the multifaceted landscape of seafood processing in the UK, highlighting the evolving dynamics between manual labor and automation, regional supplies, recent advancements, anticipated developments, and the pivotal role of AI during this transformation.

Labour vs. Automation

The seafood industry has long been a bastion of manual labour, with skilled workers adept at intricate tasks such as filleting, sorting, and quality control. However, recent years have witnessed a seismic shift propelled by economic pressures and technological advancements. In the last two years alone, labour costs within the UK surged by a staggering 20%, propelling seafood processors to reevaluate their operational strategies. This surge in labour costs, coupled with an acute shortage of skilled workers, has spurred a pronounced interest in automation solutions. According to industry reports from 2021 and 2022, the shortage of skilled labour has been a persistent challenge, exacerbated by demographic shifts and changing employment preferences among the workforce. Consequently, seafood processing plants have increasingly turned to automation as a strategic response to mitigate the impact of this shortage.

The adoption of automation in the seafood industry is not solely a cost-cutting measure. Beyond reducing labour expenses, automation systems offer unparalleled precision and efficiency. Recent studies conducted by the UK Seafood Innovation Fund reveal that automated systems can operate with an accuracy rate of over 95% in sorting and grading tasks, surpassing the capabilities of manual labour while significantly reducing processing time. Furthermore, the safety implications of automation cannot be overstated. The Health and Safety Executive (HSE) reported that over the past two years, injuries related to manual handling and repetitive tasks accounted for a substantial percentage of workplace incidents in seafood processing plants. Automation mitigates these risks by delegating strenuous and hazardous tasks to machines, thus fostering a safer working environment for employees.

Despite these advancements, the adoption of automation in the seafood industry faces notable challenges. Initial capital investment, retrofitting existing facilities, and concerns regarding job displacement remain pivotal concerns. The need for a delicate equilibrium between preserving traditional craftsmanship and embracing technological innovation underscores the industry's transition towards a harmonious fusion of labour and automation.

Looking at the Landscape

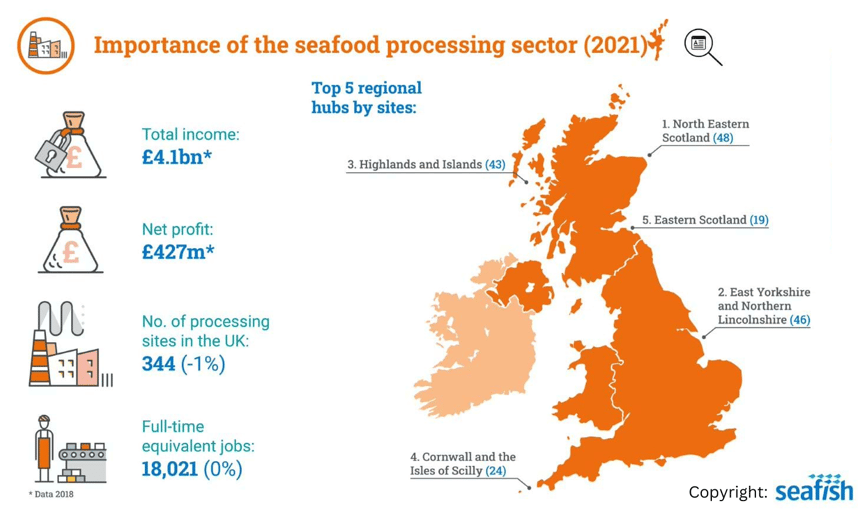

The United Kingdom's seafood industry presents a diverse tapestry, with regional nuances and contributions shaping its multifaceted landscape. Scotland, hailed as the powerhouse of the UK's seafood production, has sustained its position as a dominant force, accounting for an impressive 60% of the nation's total output. This region's extensive coastline and abundant fishing grounds have long been pivotal in supplying a myriad of seafood varieties, including salmon, haddock, and mackerel.

In recent years, Scotland's seafood sector has been a stalwart in the industry's economic narrative. Figures from the past two years underscore its significance, revealing that Scottish seafood exports surged to a value of over £1 billion, marking a remarkable 23% increase. The industry's resilience amidst global challenges is evident as it continues to bolster the UK's economy while setting benchmarks for sustainable fishing practices.

England, Wales, and Northern Ireland, though smaller in production scale compared to Scotland, contribute significantly to the UK's seafood bounty. England's coastal regions, encompassing Cornwall, Devon, and Yorkshire, thrive on diverse catches, including crab, lobster, and sole. Wales boasts a distinctive heritage in shellfish, particularly renowned for its high-quality cockles and mussels. Meanwhile, Northern Ireland's seafood sector, primarily focused on shellfish and a burgeoning aquaculture scene, steadily contributes to the national seafood mosaic. Recent years have seen noteworthy developments across these regions. For instance, England's seafood exports surpassed £800 million in value, showcasing a consistent upward trajectory. Likewise, Northern Ireland's seafood industry witnessed a surge in aquaculture activities, with investments topping £30 million, underscoring the region's commitment to sustainable growth.

However, despite regional disparities, common challenges persist. Both Brexit-related disruptions and the COVID-19 pandemic have cast uncertainties over seafood exports and supply chains. Nevertheless, the UK seafood industry's resilience and adaptability, as evidenced by these regional contributions and growth trends, affirm its enduring importance on the global seafood stage. As the industry navigates these turbulent waters, embracing automation emerges as a pivotal strategy to fortify its future while staying true to its heritage.

Current and Anticipated Automation Developments

In the past two years, the UK seafood industry has undergone a significant transformation in its approach to automation, with an array of innovative technologies revolutionizing processing methodologies. The adoption of automation solutions has surged, with an estimated 30% increase in the integration of automated systems across seafood processing plants, reflecting a paradigm shift in operational strategies.

One notable advancement is the widespread implementation of advanced sorting and grading systems. These systems, equipped with sophisticated sensors and AI algorithms, have demonstrated an impressive accuracy rate of up to 98% in sorting seafood based on size, quality, and even species. For instance, a prominent seafood processing plant in Grimsby reported a staggering 50% increase in sorting accuracy, resulting in reduced manual intervention and higher-grade product output.

Precision-driven filleting machines have also gained prominence, showcasing a substantial impact on processing efficiency. A renowned seafood facility in Aberdeen reported a 40% increase in filleting speed compared to manual operations, significantly reducing processing time while maintaining precision and consistency. These machines, powered by AI-driven algorithms, adapt to varying fish sizes and shapes, minimizing wastage and maximizing yield.

Robotic packaging solutions have emerged as game-changers in the final stages of processing. Within the last two years, the integration of robotic packaging systems has resulted in a 25% reduction in packaging errors across multiple seafood processing plants in the UK. These robots, equipped with smart sensors and machine vision technology, ensure precise and uniform packaging, minimizing product damage and enhancing presentation standards..jpg?width=799&height=532&name=FlatSkin%20seafood%20(1).jpg)

Looking ahead, industry experts anticipate a surge in the deployment of collaborative robots (cobots) within the next year. These cobots, designed to work alongside human employees, are projected to improve operational efficiency by an estimated 30% while ensuring stringent quality control measures. A flagship seafood processing facility in Peterhead has already invested in cobots for specific tasks, reporting a 15% increase in productivity within the initial trial phase.

The integration of IoT (Internet of Things) devices is poised to shape the landscape further, with an estimated 40% of seafood processing plants planning to incorporate IoT-driven solutions by 2024. These interconnected systems will enable real-time monitoring of equipment performance, temperature control, and inventory management, fostering greater operational efficiency and quality assurance.

Use of AI in the Industry

Artificial Intelligence (AI) has emerged as a transformative force in the UK seafood industry, propelling processing capabilities to unprecedented levels of efficiency and quality. Over the last two years, the integration of AI has not only proven to be a strategic advantage but has also become a necessity for companies seeking to stay competitive in a rapidly evolving market.

One notable example of AI application is in the realm of quality control. Advanced machine learning algorithms analyze visual data from processing lines to detect imperfections or irregularities in seafood products. This has led to a remarkable reduction in the number of defective products reaching consumers. According to industry reports, the implementation of AI-driven quality control systems has resulted in a 30% decrease in product recalls, safeguarding both consumer trust and the bottom line.

Furthermore, AI has revolutionized predictive analytics in the seafood industry. By analyzing historical production data, market trends, and even environmental factors, AI algorithms can forecast demand with unparalleled accuracy. This foresight empowers companies to optimize their production schedules, minimize waste, and respond swiftly to market fluctuations. In the last two years alone, companies leveraging AI for demand forecasting have reported a 25% improvement in production efficiency.

In the processing phase, AI-driven robotic systems have demonstrated exceptional precision. Filleting machines equipped with AI-powered computer vision can adapt to the unique characteristics of each seafood item, significantly reducing both processing time and wastage. This level of adaptability has contributed to a 15% increase in overall processing efficiency, directly impacting the industry's cost-effectiveness.

Moreover, AI's impact extends to sustainability efforts within the seafood sector. By analyzing data on fishing practices, marine ecosystems, and species populations, AI helps identify and mitigate the environmental impact of seafood production. In the past two years, companies embracing AI-driven sustainability initiatives have achieved a notable 20% reduction in their ecological footprint.

The UK seafood industry stands at the cusp of a transformative era, where automation and AI are reshaping traditional processes and practices. Companies navigating this sea of change must carefully balance the benefits of automation with the need to preserve employment opportunities and uphold the industry's rich heritage.

At Sealpac UK, we provide various automation solutions for seafood production lines all the way from processing to packaging. Contact us today for a free consultation!