Ready Meals

The demands and eating habits of consumers are constantly evolving. Smaller, healthier and more convenient tasty treats, snacks and ready-to-serve meals are popular.

To keep up with demand, speed, flexibility and accuracy are key to optimising your production along with automated labour-saving options. Our full-line solutions weigh, fill and pack a wide range of ready meal products into trays, pots, pouches, bags or any other container. From traditional to innovative new developments – we’ve got it covered.

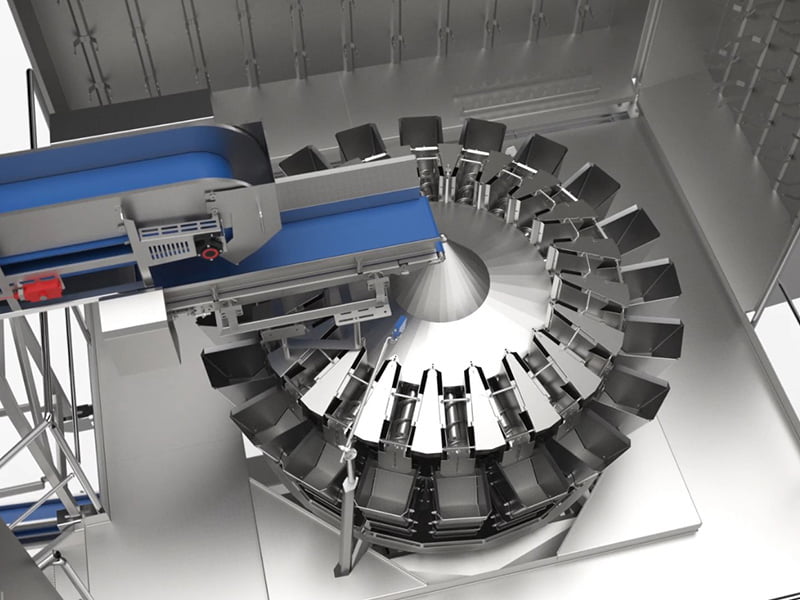

Weighing and distribution of difficult to handle products

Inventors of the screw feed system for multihead weighing, Cabinplant are specialists in handling complex, sticky fresh and cooked products at speed. Perfect for minimising damage to products like marinated chicken, noodles, wet-sticky pasta plus many more.

- Handle multiple products on the same system

- Super easy product change-overs

- Minimize give-away

- Eliminate re-work and reduce labour costs

- Increase speed and throughput

High speed liquid filling and depositing

Our range of filling and depositing systems ensures precise pre- or final post-filling of liquids like tomato sauce, oil and brine, soups, or marinades into containers.

- 1-12 filling heads per cycle

- Flexible – totally adjustable filling volumes

- From liquids to chunky pumpable products (up to 40mm chunks)

- Waste saving no-container, no-fill system

- Hygienic, easy to dismantle and clean

- Small machine footprint

Re-closable trays in one sealing process – EasyLid®

Creating maximum efficiency, EasyLid® is a unique concept for re-closable trays and pots that provides full lid function in just one sealing process, while using less materials. It also addresses consumer demands for optimal convenience, maximum shelf life and sustainability.

- No lidding machine required or operators for lid application

- Shorter production line with less processes.

- Very easy to open and close with no loss of lids at retail

- Significant savings in packaging time, materials and weight

- Reduction in transport and storage costs

- Available in mono PP for recyclability

- Can be further processed in high pressure or retort.

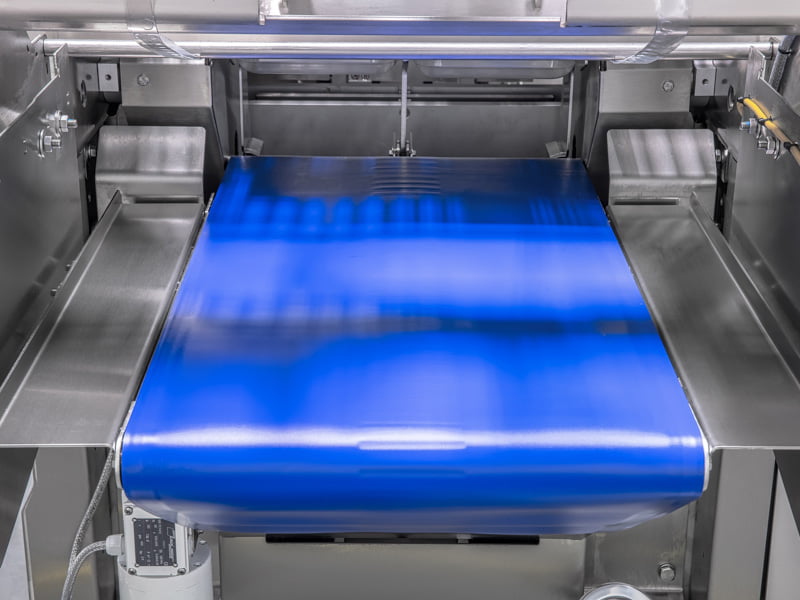

Mess free in-line marinating system

By marinating products after portion weighing, this Cabinplant system ensures other machines in your production line are not soaked in marinade. This reduces cleaning time significantly. The system is also perfect in scenarios where different flavours of marination are required throughout a production day.

- Excellent weighing accuracy and no spillage

- Minimum maintenance and easy cleaning

- No marinade on conveyor and multi-head weigher

- No give-away when handling small negative tolerances

- Meets market demands for small batch production

Recommended Products

How can you benefit from our expertise?

Whatever your production line requirements, we have the expertise that can really make a difference to your overall efficiency and operating costs. Get in touch with us today to arrange a consultation with our expert team and let’s explore the possibilities.

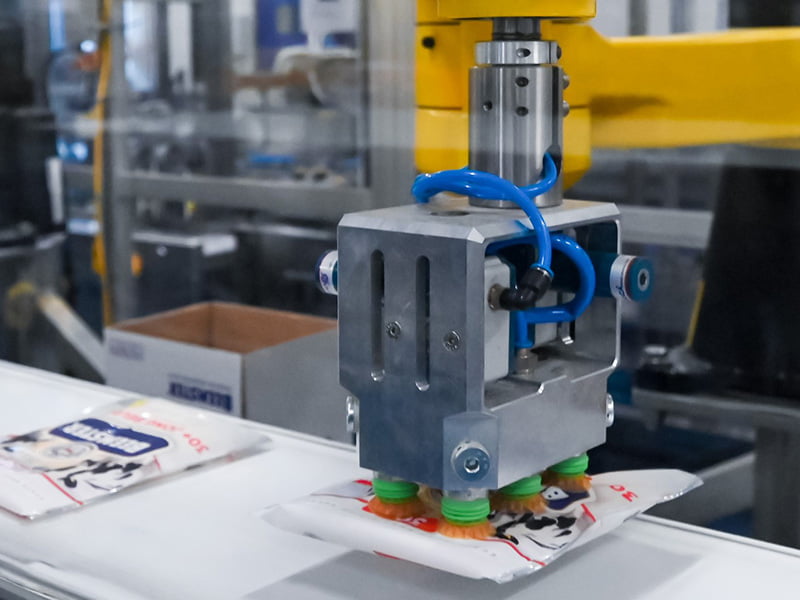

Full line solutions

We design and project manage the installation of bespoke machines across the full production line. Our network of partnerships has helped us to expand our range to offer automated full line solutions which are flexible enough to fit around your business needs and respond to a changing market.